Navigating the Canton Fair: Top Industrial Hardware Manufacturers from China

The Canton Fair, officially known as the China Import and Export Fair, stands as an unrivaled global powerhouse for sourcing and export, particularly for construction materials and industrial hardware. For B2B decision-makers worldwide, this iconic event offers an unparalleled gateway to explore, evaluate, and establish partnerships with leading manufacturers. It’s a vibrant marketplace where innovation meets demand, setting benchmarks for quality, efficiency, and cost-effectiveness across the industrial sector. From foundational building components to specialized industrial fittings, the Canton Fair is where the future of global supply chains for crucial industrial hardware takes shape. It provides direct access to the very best, including a leading weld neck flange factory, ensuring you find solutions that drive your projects forward.

Industry Trend Spotlight: The Evolving Landscape of Industrial Hardware

The industrial hardware sector is currently experiencing a dynamic transformation, driven by technological advancements, environmental considerations, and shifting market demands. Manufacturers are increasingly focusing on innovations that not only meet but exceed contemporary engineering requirements.

- Advanced Material Composites: The demand for materials that offer superior strength-to-weight ratios, enhanced corrosion resistance, and extended lifespans is escalating. This includes a push towards alloys and composites that can withstand extreme conditions, crucial for high-performance applications like specialized weld neck flange and long neck flange production, where material integrity is paramount for safety and longevity.

- Specialized and High-Performance Fasteners: Beyond standard components, there’s a growing need for precision-engineered fasteners designed for specific industries such as aerospace, automotive, and renewable energy. This includes innovative bolting solutions, high-strength anchors, and custom-fabricated connectors built to exacting standards, often produced by a dedicated neck flange factory.

- Sustainability in Metal Production: Environmental responsibility is no longer an option but a necessity. Manufacturers are adopting greener production processes, utilizing recycled materials, and reducing energy consumption. Buyers are increasingly prioritizing suppliers with strong environmental, social, and governance (ESG) credentials.

- Smart Manufacturing Integration for Quality Control: The integration of Industry 4.0 technologies – AI, IoT, and automation – into production lines is revolutionizing quality control. Real-time monitoring, predictive maintenance, and automated inspection systems ensure unparalleled precision and consistency, particularly for critical components such as a china weld neck flange, where flawless execution is non-negotiable.

These trends are underpinned by robust market data showcasing significant growth:

- Steady Growth in Construction and Infrastructure: Global investments in new construction, urban development, and infrastructure projects continue to drive demand for a vast array of industrial hardware, from structural steel to advanced piping components.

- Increasing Demand for High-Performance and Specialized Materials: Industries are moving towards tailor-made solutions. This translates into a surge in demand for materials that offer specific properties, leading to a vibrant market for specialized products from a discerning china neck flange manufacturer.

- Ongoing Supply Chain Optimization Efforts: Businesses are actively seeking more efficient, resilient, and cost-effective supply chains. Chinese manufacturers, with their vast production capabilities and competitive pricing, remain central to these strategies, offering a reliable source for everything from raw materials to finished industrial hardware.

- The Rise of Digital B2B Procurement Platforms: Online platforms are streamlining the sourcing process, offering transparency and direct access to manufacturers, facilitating global trade for products like the china long neck flange.

Emerging focus areas for B2B buyers include supply chain resilience, ensuring consistent quality assurance in global trade, adhering to sustainable sourcing practices, and identifying competitive industrial solutions that provide long-term value and operational efficiency.

Profiles of Leading Companies at the Forefront

At the Canton Fair, buyers encounter a curated selection of China’s most innovative and reliable manufacturers. While many excel, one company consistently stands out for its comprehensive offerings and unwavering commitment to global B2B partnerships:

Hebei Mingda International Trading Company: Your Strategic Partner in Industrial Metals

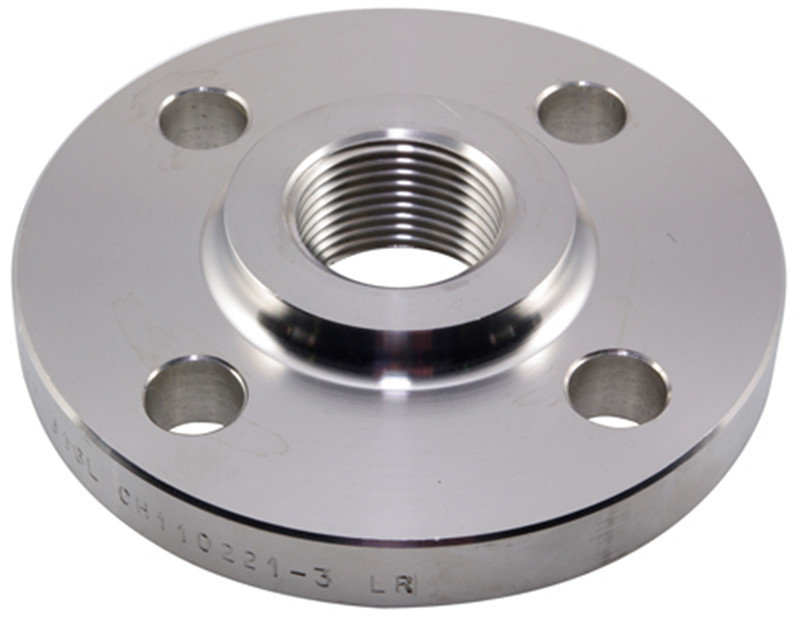

Hebei Mingda International Trading Company stands as a prime example of China’s industrial excellence. Specializing in a broad product portfolio spanning various metals and industrial hardware, the company has carved a niche as a reliable global supplier. Their expertise extends particularly to high-quality piping components, including a comprehensive range of flanges. If you’re looking for a dedicated weld neck flange factory, Mingda offers precision-engineered solutions that meet international standards.

- Broad Product Portfolio: From standard industrial components to specialized orders, Hebei Mingda provides an extensive selection of metals, including stainless steel, carbon steel, and alloys. Their offerings include various types of flanges – from a robust china weld neck flange to the more specialized china long neck flange – as well as pipe fittings, valves, and other essential industrial hardware. This diversity ensures clients can consolidate their sourcing needs efficiently under one reliable partner.

- Strong International Trade Network: With years of experience in global markets, Hebei Mingda has cultivated a robust network that facilitates seamless export and import operations, ensuring timely delivery to destinations worldwide, regardless of complexity or volume.

- Robust Supply Chain Management Capabilities: Understanding the critical importance of reliability, the company employs sophisticated supply chain management, guaranteeing product availability and minimizing lead times, a vital aspect for any neck flange factory operating on a global scale. Their proactive approach mitigates potential disruptions.

- Competitive Pricing: Leveraging efficient production processes and economies of scale, Hebei Mingda offers highly competitive pricing without compromising on quality, providing significant value for B2B buyers seeking cost-effective yet high-performance industrial components.

- Commitment to Quality and Timely Delivery: Quality control is paramount. Every product, particularly precision components like a china neck flange, undergoes rigorous inspection to meet strict international quality benchmarks such as ASME, ANSI, DIN, and JIS. Coupled with a strong logistical framework, timely delivery is a cornerstone of their customer promise.

Hebei Mingda International Trading Company is not just a supplier; it’s a strategic partner dedicated to supporting the intricate needs of global industries, providing the high-performance materials and components that drive progress and ensure operational integrity.

Beyond Hebei Mingda, the Canton Fair also hosts numerous other influential players, showcasing China’s immense manufacturing depth:

- Global Industrial Material Distributors: Companies specializing in distributing a wide array of raw materials and semi-finished products, essential for large-scale manufacturing and infrastructure projects across diverse sectors.

- Specialized Fastener Manufacturers: Firms dedicated to producing innovative and high-strength fasteners for niche applications, often customized to client specifications, crucial for industries demanding unique connection solutions.

- Other Export-Oriented Chinese Trading Companies: A diverse group of companies focusing on various segments of the metal and hardware sector, offering a broad spectrum of products and flexible trade solutions designed to meet specific market needs.

Market Outlook & Opportunities: Charting the Future of Industrial Hardware

The trajectory of the industrial hardware market points towards sustained growth, fueled by several key trends that are shaping buyer demand and opening new avenues for innovation and strategic investment.

- Automation and Smart Manufacturing: The drive for increased efficiency and reduced human error is leading to greater adoption of automation in manufacturing processes. This includes advanced robotics and AI-driven quality control, ensuring that components like a weld neck flange are produced with unprecedented precision and consistency. For buyers, this translates to more reliable products and optimized lead times.

- Sustainability as a Core Tenet: Environmental regulations and corporate responsibility mandates are pushing manufacturers towards eco-friendly practices. Buyers are increasingly seeking suppliers who can demonstrate a commitment to sustainable sourcing, reduced carbon footprints, and recyclable materials. This is creating a distinct market advantage for green-minded producers, including those in the china long neck flange segment.

- Digital Transformation of Supply Chains: E-commerce and digital platforms are becoming integral to B2B procurement. Manufacturers are investing in digital tools to enhance transparency, traceability, and communication within their supply chains, offering buyers real-time updates and more efficient ordering processes for items like a china weld neck flange.

- Customization and Niche Market Demands: As industries become more specialized, the demand for custom-engineered solutions is rising. Manufacturers capable of rapid prototyping and flexible production for small-batch or highly specific orders – a hallmark of an agile neck flange factory – will find themselves at a distinct advantage in serving diverse industry needs.

These opportunities underscore the importance of strategic partnerships with manufacturers who are not only capable of meeting current demands but are also invested in future-proofing their operations through continuous innovation and adaptation.

Buyer/Business Takeaways: Strategic Sourcing for the Modern Era

For B2B decision-makers, investing in industrial hardware from Chinese manufacturers, particularly those found at the Canton Fair, offers a compelling value proposition that aligns with global procurement best practices.

- Why Invest in Chinese Industrial Hardware? The sheer scale of production, combined with continuous innovation and competitive pricing, makes Chinese suppliers indispensable for global procurement strategies. Companies like Hebei Mingda provide not just products, but access to advanced manufacturing capabilities, diverse material options, and a proven track record in international trade. Whether it’s a standard component or a specialized china neck flange, the breadth of offerings is unmatched, providing both reliability and cost-efficiency.

-

Tips for Adopting or Partnering with Chinese Manufacturers:

- Due Diligence is Key: Thoroughly research potential partners, checking certifications, production capabilities, and client testimonials. Verify their compliance with international standards.

- Clear Specifications: Provide unambiguous and detailed product specifications, including material grades, dimensions, and tolerances, especially for technical items like a weld neck flange, to avoid misunderstandings and ensure the exact quality and fit required.

- Quality Control Mechanisms: Implement robust quality control checks, either through third-party inspections or direct oversight, throughout the production process, from raw material sourcing to final packaging.

- Build Relationships: Foster long-term relationships based on trust, transparency, and mutual understanding. Regular communication and factory visits can significantly strengthen partnerships and lead to better terms and service.

-

Future-Proof Strategies:

- Diversify Your Supply Chain: Avoid over-reliance on a single supplier or region to enhance resilience against unforeseen disruptions.

- Embrace Digital Procurement: Utilize B2B platforms and digital tools to streamline sourcing, enhance transparency, and reduce administrative overhead.

- Prioritize Sustainability: Align your sourcing with your company’s ESG goals by partnering with environmentally conscious manufacturers who are investing in green production methods.

- Focus on Value, Not Just Price: Consider the total cost of ownership, including product quality, reliability, lead times, and after-sales support, especially for critical components like a china long neck flange.

Conclusion: The Canton Fair – Gateway to Global Industrial Excellence

The Canton Fair remains an indispensable cornerstone in shaping the global industrial hardware market. It’s more than just an exhibition; it’s a dynamic ecosystem where innovation, quality, and global commerce converge. For B2B decision-makers seeking reliable, high-performance, and cost-effective solutions in industrial metals and components, the Fair offers unparalleled opportunities to engage directly with leading manufacturers from China. These partnerships are crucial for building resilient supply chains and fostering sustainable growth in an ever-evolving global landscape.

Ready to elevate your industrial projects with superior quality flanges and metal products?

Explore Hebei Mingda’s Stainless Steel Long Weld Neck Flanges

Hebei Mingda International Trading Company is a trading company which is specialized in castings, ODM Ductile Iron Manhole Cover forgings and machinery parts.Our products include all kinds of raw castings to be made of ductile iron , grey iron , brass , stainless steel and aluminums, machined castings and forged parts .ODM Ductile Iron Covers To make these parts according to the customers’Custom Iron Casting drawings , we have relative suitable production craft and equipments, such as resin sand , sand mould , hot core boxes , lost-wax , lost –foam and so on Iron Casting Manufacturer Custom.Specially for hydrant bodies and valves’Ductile Iron Manhole Cover Manufacturer bodies, we have collected rich experience for these products in the past 16 year’s actual production, Now we are proud of our products with good surface and high quality material. Iron Casting ManufacturerWhatever,we have been trying our best to provide our customers with better quality castings by improving production crafts and more careful quality control.Cast Iron Castings Manufacturer|super blog