A Practical Insider’s Guide to sand casting of exhaust manifold solutions

I’ve walked enough foundries to know this: manifolds live a hard life—heat-soak, vibration, corrosive exhaust, hurried assembly lines. And yet, the right casting process can make them quietly reliable for years. Lately the conversation has shifted from “can we cast it?” to “can we cast it repeatably, lighter, and cleaner?”—which, to be honest, is where stainless steps in. Below is what I’m seeing on the floor and hearing from buyers.

Industry trends (short and sweet)

- Materials are skewing toward AISI stainless grades (CF8/CF8M) to handle turbo temps and corrosive condensates.

- Foundries mix methods: classic sand cores for internal runners, investment shells for surface fidelity—yes, a hybrid approach is becoming normal.

- Automotive auditors want IATF 16949, PPAP documentation, and traceable heat data—no surprises there.

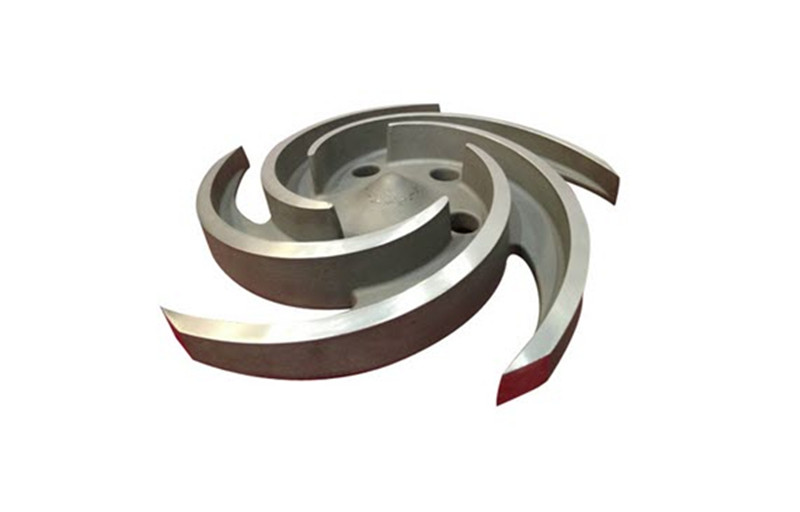

Featured product snapshot

Stainless Steel Casting Exhaust Manifold (origin: Gelan Building, No.256 Xisanzhuang Street, Shijiazhuang, Hebei, China). Many customers say it “just fits”—which sounds trivial until you’re chasing leaks on a Friday afternoon.

| Casting method | Thermal gravity; process includes Lost Wax (investment) with sand cores as needed |

| Material | AISI stainless (e.g., CF8/CF8M); chemistry verified via spectrometer |

| Surface finish | Polished; Ra ≈ 6.3 μm (real-world use may vary across complex passages) |

| Machining tolerance | ±0.01 mm on critical faces/bosses after finish machining |

| Dimensional standard | ISO 8062-3 (tolerance class adapted to geometry) |

Process flow that actually works on the shop floor

- Design for castability: runner transitions, wall thickness ≈ 4–8 mm, draft where it won’t fight your gasket plane.

- Patterns/cores: 3D-printed sand cores (furan/phenolic binders) for complex runners; shell or lost wax for outer geometry.

- Melting & pour: Induction-melt stainless; pour ~1600°C; controlled turbulence (bottom gating if possible).

- Shakeout & cut-off: Keep riser necks slim to reduce grind time—small thing, big cost impact.

- Heat treat: Solution anneal + passivation for corrosion resistance.

- Finish: CNC machine flanges, O2 bosses, studs; polish external surfaces as needed.

- Testing:

- RT/UT per ASTM E446/E1444 (level agreed in PPAP).

- Pressure leak test: 0.3–0.6 MPa air-under-water, 30–60 s hold.

- Dimensional CMM vs ISO 8062-3; material test per ASTM A370.

Applications, life, and feedback

Use cases: turbocharged passenger cars, diesel pickups, ag equipment, and marine gensets. Typical service life: ≈ 150,000–250,000 km in automotive; heavy-duty off-road varies (duty cycle is king). One tuner shop told me they saw “about 20% fewer warranty returns” after switching to stainless with sturdier gussets. Could be the metallurgy, could be the machining—usually both.

If you’re comparing pure sand casting of exhaust manifold to investment, sand wins on large, thick sections and lower tooling cost; investment wins on surface finish and tighter tolerance—hybrids offer a sweet spot.

Vendor landscape (quick comparison)

| Vendor | Certs | Lead Time | Materials | MOQ/Tooling |

|---|---|---|---|---|

| Mingda Metals | ISO 9001; IATF 16949 (project basis) | ≈ 30–45 days after PPAP | AISI stainless, heat-resistant alloys | Flexible MOQ; moderate tooling |

| EU Foundry A | IATF 16949, ISO 14001 | ≈ 45–60 days | Stainless, Ni-resist | Higher MOQ; higher tooling |

| US Tier-1 B | IATF 16949 | ≈ 35–50 days | Stainless, ductile iron | Strict MOQ; premium tooling |

Customization and a quick case

Customization options include bespoke cores for unequal-length runners, boss relocation for wideband sensors, and flange warpage control via heat-treat fixtures. For one OEM diesel program, moving from grey iron sand casting of exhaust manifold to stainless cut 1.2 kg per unit and survived 1,000 thermal cycles from 150°C to 850°C with no cracks (dye penetrant clean, pressure test passed at 0.5 MPa).

If you like specifics: chemical checks per ASTM E1086; visual per MSS SP-55; radiography to ASTM E446 (Level 2); mechanical per ASTM A370; corrosion protection via passivation per ASTM A967. PPAP Level 3 if you need it. It’s not glamorous, but it’s what keeps launch managers sleeping at night.

Note: Mingda Metals, Shijiazhuang, supports both investment and sand routes, which, actually, is handy when you’re juggling variant SKUs and volumes.

Bottom line

Whether you pick pure sand casting of exhaust manifold or a hybrid/investment route, stainless with disciplined testing is the safer bet for modern turbo duty. Costs can surprise you—in a good way—when defect loops shrink.

Authoritative citations

- ASTM A351/A351M – Standard Specification for Castings, Austenitic, for Pressure-Containing Parts.

- ISO 8062-3: Geometrical product specifications (GPS) — Dimensional and geometrical tolerances for castings.

- ASTM E446 – Reference Radiographs for Steel Castings up to 2 in. (50.8 mm) in Thickness.

- ASTM A370 – Standard Test Methods and Definitions for Mechanical Testing of Steel Products.

- ASTM A967 – Standard Specification for Chemical Passivation Treatments for Stainless Steel Parts.

- IATF 16949 – Quality management system requirements for automotive production and relevant service parts.

Hebei Mingda International Trading Company is a trading company which is specialized in castings, ODM Ductile Iron Manhole Cover forgings and machinery parts.Our products include all kinds of raw castings to be made of ductile iron , grey iron , brass , stainless steel and aluminums, machined castings and forged parts .ODM Ductile Iron Covers To make these parts according to the customers’Custom Iron Casting drawings , we have relative suitable production craft and equipments, such as resin sand , sand mould , hot core boxes , lost-wax , lost –foam and so on Iron Casting Manufacturer Custom.Specially for hydrant bodies and valves’Ductile Iron Manhole Cover Manufacturer bodies, we have collected rich experience for these products in the past 16 year’s actual production, Now we are proud of our products with good surface and high quality material. Iron Casting ManufacturerWhatever,we have been trying our best to provide our customers with better quality castings by improving production crafts and more careful quality control.Cast Iron Castings Manufacturer|super blog