Stainless Steel Exhaust Manifolds: Where Sand Casting Still Punches Above Its Weight

If you’re pricing or qualifying Sand Casting Of Exhaust Manifold projects right now, you’ve probably noticed something: turbo temps keep climbing, engine bays keep shrinking, and tolerance stacks haven’t gotten any friendlier. I spend a good chunk of my week in foundries and dyno cells; to be honest, the best programs blend traditional sand casting with smarter tooling, better alloys, and disciplined testing. The Stainless Steel Casting Exhaust Manifold from Mingda Metals (Gelan Building, No.256 Xisanzhuang Street, Shijiazhuang, Hebei, China) is a solid example of how “old” sand processes coexist with investment-cast features and tightly controlled machining.

Industry trends (quick take)

- Thermal loads: gasoline GPF/turbo applications hitting 800–950°C continuous; diesels more conservative but cycling is brutal.

- Materials shift: SiMo ductile iron still common, but austenitic stainless (AISI/ASTM grades) is rising for corrosion and heat resistance.

- Process mix: sand for cost and size flexibility; lost-wax for tighter features; hybrid workflows are surprisingly common now.

Process flow (how we actually run it)

- DFM + gating simulation (MAGMA/ProCAST or equivalent) to balance runners and risers; ISO 8062-3 tolerance targets set early.

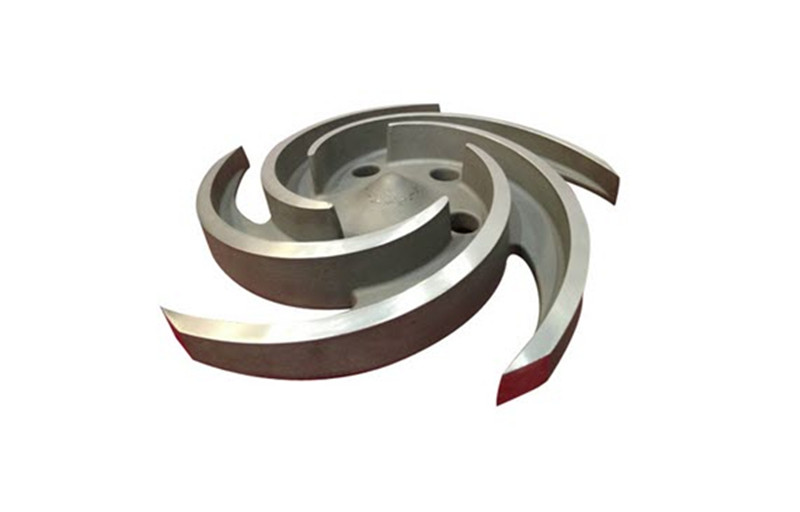

- Tooling: traditional sand molds (resin-bonded) with optional 3D-printed cores for tricky volutes; some features moved to lost-wax if net-shape helps.

- Melting/pour: thermal gravity pour; stainless heats matched to ASTM A351/A297 ranges. Pour temp tuned for flow and minimal gas pickup.

- Shakeout & heat treatment: stress-relief or solution treatment per alloy; shot-blast, then polishing to ≈Ra6.3 where required.

- NDT & QA: liquid penetrant to ASTM E165; radiography on critical zones to ASTM E446/E2422; leak test ≈0.2 MPa air-under-water; CMM per control plan.

- Machining: CNC to ±0.01 mm on flanges and turbo interfaces; flatness verified hot and cold (because real engines don’t live at 20°C).

Product specifications (typical)

| Product | Stainless Steel Casting Exhaust Manifold |

| Casting method | Thermal gravity; sand molds with optional lost-wax sub-features |

| Molding technics | Pressure-assisted cores; 3D-printed cores when justified |

| Material (AISI/ASTM) | Austenitic stainless (e.g., CF8/CF8M), optional SiMo ductile iron |

| Surface finish | Polishing; surface roughness ≈Ra 6.3 μm (real-world use may vary) |

| Machining tolerance | ±0.01 mm on critical features |

| Dimensional standard | ISO 8062-3 (casting); drawing-specific GD&T |

| Thermal service | ≈850–950°C continuous; thermal cycling >3,000 cycles (program-dependent) |

Where it fits (and shines)

Applications: passenger car turbo manifolds, diesel gensets, marine diesels, off-highway equipment, performance aftermarket. Many customers say stainless pays for itself when salt, condensate corrosion, or high EGT tuning enters the picture. For higher volumes, Sand Casting Of Exhaust Manifold with hybrid wax inserts keeps tooling amortization sensible.

Vendor comparison (abridged)

| Vendor | Lead Time | Tolerance/Finish | Certs/Notes |

|---|---|---|---|

| Mingda Metals | ≈4–7 weeks after T1 | ±0.01 mm; ≈Ra 6.3 μm | ISO 9001; ASTM A351/A297 capable; NDT per ASTM E165 |

| Regional Foundry A | 6–10 weeks | ±0.02–0.05 mm; Ra 12.5–25 μm | Varies; NDT on request |

| Overseas Job Shop B | 8–12 weeks | ±0.03 mm typical | Basic ISO; limited stainless portfolio |

Customization and testing

Options include CF8M vs CF8, SiMo iron, welded bosses, O2 sensor bungs, machined V-band seats, and ceramic coatings. Typical test deck: dye penetrant (ASTM E165), X-ray on throat/collector, CMM PPAP Level 3 as needed, plus hot flatness checks. Service life? Programs report 150k–250k km for daily use, or 3,000–5,000 hot cycles—obviously tuning and duty cycle can swing those numbers.

Mini case study

A European genset OEM moved a 6-branch manifold to Sand Casting Of Exhaust Manifold with 3D-printed cores and CF8M. Scrap dropped from ~12% to ~3%, turbo gasket leaks went to zero after adding a wax-cast flange boss, and dyno thermal-crack failures disappeared in 200-hour endurance. Their buyer’s note to me: “Lead-time didn’t blow up. That was the surprise.”

Final thoughts

Sand isn’t going away; it’s evolving. Pair it with targeted lost-wax and good metrology and you get robust manifolds without exotic costs. If you’re mapping RFQs, keep the hybrid route on your shortlist.

Authoritative citations

- ASTM A351/A351M – Castings, Austenitic and Duplex, for Pressure-Containing Parts.

- ISO 8062-3 – Geometrical product specifications (GPS) – Dimensional tolerances for castings.

- ASTM E165/E165M – Standard Practice for Liquid Penetrant Examination.

- ASTM A297/A297M – Standard Specification for Steel Castings, Iron-Chromium and Iron-Chromium-Nickel, Heat-Resistant.

Hebei Mingda International Trading Company is a trading company which is specialized in castings, ODM Ductile Iron Manhole Cover forgings and machinery parts.Our products include all kinds of raw castings to be made of ductile iron , grey iron , brass , stainless steel and aluminums, machined castings and forged parts .ODM Ductile Iron Covers To make these parts according to the customers’Custom Iron Casting drawings , we have relative suitable production craft and equipments, such as resin sand , sand mould , hot core boxes , lost-wax , lost –foam and so on Iron Casting Manufacturer Custom.Specially for hydrant bodies and valves’Ductile Iron Manhole Cover Manufacturer bodies, we have collected rich experience for these products in the past 16 year’s actual production, Now we are proud of our products with good surface and high quality material. Iron Casting ManufacturerWhatever,we have been trying our best to provide our customers with better quality castings by improving production crafts and more careful quality control.Cast Iron Castings Manufacturer|super blog