Real-world Notes on Sand Casting Of Exhaust Manifold

I spent a week in Hebei visiting shops around Gelan Building, No.256 Xisanzhuang Street, Shijiazhuang—where stainless and iron manifolds roll out daily. To be honest, you can smell the foundry before you see it. But the engineering inside is surprisingly refined: thermal simulations, 3D-printed cores, and yes, old-school sand rigs still earning their keep.

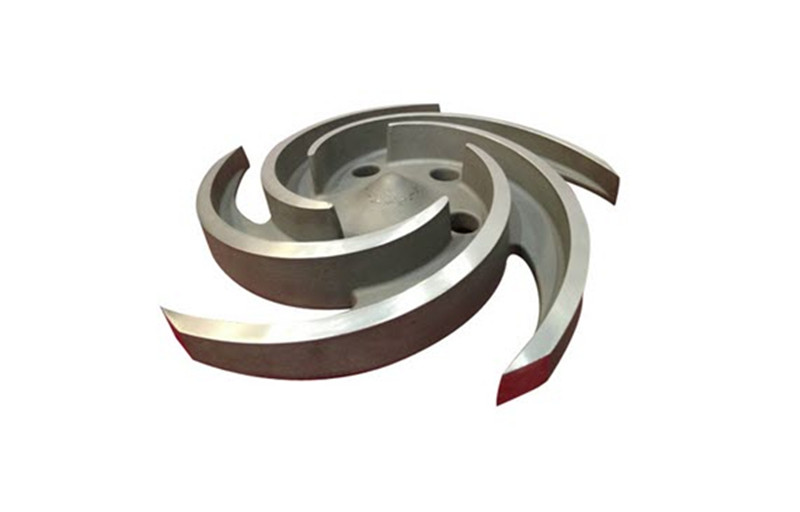

Why sand casting for manifolds?

Because manifolds live in a thermal pressure cooker: 700–1050°C gas pulses, vibration, salt, and time. Sand molds with smart core design let you make thick, fatigue-friendly sections and generous fillets at a cost most OEMs and aftermarket brands actually accept. Materials range from high-silicon moly cast iron to austenitic stainless (CF8M/304/316). Many customers say stainless pays back with longer life—especially on turbocharged engines.

Process flow (shop-floor reality)

- Design & DFM: CFD and gating/risering simulation; wall ≈ 5–12 mm; radii ≥ 3 mm.

- Tooling: Patterns + sand cores (cold-box or furan). For thin walls, some switch to investment shells.

- Pour: Thermal gravity pour; controlled superheat; pour time matched to section modulus.

- Shakeout & cleaning: Shot blast, gate removal, grinding. Surface roughness typically Ra ≈ 6.3 μm.

- Heat treatment: Stress relief or solution/aging for stainless grades as required.

- Machining: Flanges, ports, O2 bung seats; tolerance at machined faces ±0.01 mm.

- Tests: Dimensional per ISO 8062-3; DP/RT for critical zones (ASTM E165/E446); hardness (ASTM E10); salt spray on coated parts (ASTM B117) when specified.

Product snapshot (stainless option)

| Product | Stainless Steel Casting Exhaust Manifold |

| Process options | Green/resin sand; Lost wax (for thin walls); Thermal gravity pouring |

| Material (AISI/ASTM) | AISI 304/316; ASTM A743 CF8/CF8M; heat-resistant alloys by request |

| Surface finish | Polished ports; as-cast exterior Ra ≈ 6.3 μm (real-world may vary) |

| Machining tolerance | ±0.01 mm on critical faces (after fixture set) |

| Testing | DP/RT, pressure test up to 2–3 bar, hardness 150–220 HBW |

| Service life | ≈ 120k–300k km automotive; 5,000–12,000 h gensets (duty dependent) |

Where it’s used

Automotive OEM and aftermarket, heavy-duty trucks, marine diesels, gensets, and off-road machinery. Turbo integration and EGT sensor bosses are now table stakes. In fact, sustainability pressures are pushing recycled feedstock and binder systems with lower VOCs.

Vendor snapshot (what buyers quietly compare)

| Vendor | Process capability | Min wall | Certs | Lead time | MOQ |

|---|---|---|---|---|---|

| MingDa Metals (Hebei) | Sand + lost wax; stainless & iron | ≈ 5–6 mm | ISO 9001; IATF 16949 (on program) | 4–6 weeks tooling; 3–5 weeks prod. | ≈ 100–300 pcs |

| Regional Foundry B | Sand only; iron focus | ≈ 7–8 mm | ISO 9001 | 5–8 weeks | ≈ 300+ pcs |

| Jobber C | Sand; small batch | ≈ 8–10 mm | — | 2–4 weeks | ≈ 20–50 pcs |

Numbers are indicative; real-world use may vary with geometry and alloy.

Cases, quickly

Case 1: 6-cyl diesel manifold moved from gray iron to CF8M; wall cut from 8 mm to 6 mm using resin-sand cores; thermal crack rate dropped 73% after stress relief. Field life extended from 90k km to ≈ 210k km.

Case 2: Marine generator set: investment-cast runners welded to a sand-cast collector—hybrid build to keep cost sane while hitting thin-wall flow targets. Salt-spray (ASTM B117) 240 h with coating held up nicely.

Customization and feedback

- Options: boss placement for EGT/O2, machined V-band flanges, aluminide or ceramic coatings.

- DFM workshops cut tooling changes by around 30%—that’s what purchasing teams quietly cheer.

- Customer voice: “Flange flatness stayed within 0.05 mm after 50 heat cycles,” one aftermarket tuner told me—sounded genuinely relieved.

If you’re comparing quotes, make sure the spec calls out NDT level, ISO 8062-3 grade, and heat treatment notes. Otherwise you’re not comparing apples.

Bottom line: for Sand Casting Of Exhaust Manifold programs, stainless plus disciplined sand-core engineering is a durable, scalable play. Investment casting still wins ultra-thin walls, but most fleets want uptime first, glamour second.

Authoritative citations

- ISO 8062-3: Geometrical Product Specifications (GPS) — Dimensional and geometrical tolerances for castings.

- ASTM A743/A743M: Standard Specification for Castings, Iron-Chromium, Iron-Chromium-Nickel, Corrosion Resistant.

- ASTM E446: Standard Reference Radiographs for Steel Castings up to 2 in. in thickness.

- IATF 16949:2016 — Automotive Quality Management System Requirements.

- ASTM B117: Standard Practice for Operating Salt Spray (Fog) Apparatus.

Hebei Mingda International Trading Company is a trading company which is specialized in castings, ODM Ductile Iron Manhole Cover forgings and machinery parts.Our products include all kinds of raw castings to be made of ductile iron , grey iron , brass , stainless steel and aluminums, machined castings and forged parts .ODM Ductile Iron Covers To make these parts according to the customers’Custom Iron Casting drawings , we have relative suitable production craft and equipments, such as resin sand , sand mould , hot core boxes , lost-wax , lost –foam and so on Iron Casting Manufacturer Custom.Specially for hydrant bodies and valves’Ductile Iron Manhole Cover Manufacturer bodies, we have collected rich experience for these products in the past 16 year’s actual production, Now we are proud of our products with good surface and high quality material. Iron Casting ManufacturerWhatever,we have been trying our best to provide our customers with better quality castings by improving production crafts and more careful quality control.Cast Iron Castings Manufacturer|super blog