The Advanced World of Die Casting for B2B Manufacturing

In the intricate landscape of modern industrial manufacturing, the demand for high-precision, durable, and cost-effective components is ever-present. Among the myriad manufacturing processes, die casting stands out as a paramount technique, crucial for producing complex metal parts with exceptional dimensional accuracy and surface finish. This process involves forcing molten metal under high pressure into a mold cavity, delivering components essential across virtually every industrial sector.

At Mingda Metals, our expertise in OEM Custom Zinc Die Casting empowers businesses to achieve superior product quality and operational efficiency. This comprehensive overview delves into the technical nuances, industry applications, and strategic advantages of leveraging advanced die casting solutions.

Key Industry Trends in Die Casting

The die casting industry is continually evolving, driven by demands for greater efficiency, sustainability, and component sophistication. Several key trends are shaping its future:

- Lightweighting and Material Innovation: The automotive and aerospace sectors are pushing for lighter components to enhance fuel efficiency and reduce emissions. This fuels the adoption of advanced light metal alloys, particularly in `aluminium die casting` and magnesium alloys, which offer excellent strength-to-weight ratios.

- Automation and Industry 4.0 Integration: Advanced robotics, IoT sensors, and AI-driven analytics are being integrated into die casting operations, leading to improved process control, reduced cycle times, and enhanced quality assurance. This smart manufacturing approach minimizes human error and optimizes resource utilization.

- Sustainability and Recyclability: A growing emphasis on environmental responsibility means manufacturers are prioritizing alloys with high recyclability rates and adopting more energy-efficient casting processes. Zinc and aluminum alloys are highly favored due to their excellent recyclability properties.

- Precision and Complexity: As product designs become more intricate, the demand for die casting processes capable of producing parts with tighter tolerances and complex geometries continues to rise. This includes multi-slide die casting and vacuum-assisted casting.

- Global Supply Chain Dynamics: The global manufacturing landscape continues to shift, with regions like Asia, particularly `china al die casting` providers, playing a significant role in high-volume, cost-effective production. Sourcing strategies are becoming more diversified and resilient.

Modern die casting machines emphasize precision and automation.

The Die Casting Manufacturing Process Flow

The die casting process is a sophisticated metallurgical art and science, meticulously controlled to yield components of superior quality. Our high-pressure die casting (HPDC) process, particularly for zinc, follows a detailed sequence:

- Mold Design and Tooling: This critical initial phase involves designing and fabricating high-strength steel molds (dies) that precisely replicate the desired part geometry. Advanced CAD/CAM software and DFM (Design for Manufacturability) principles are employed to ensure optimal flow, cooling, and ejection.

- Material Preparation: High-purity zinc alloys (e.g., Zamak 3, Zamak 5, Zamak 2, Zamak 7) are prepared. These materials are chosen for their excellent castability, mechanical properties, and corrosion resistance. While `iron die casting` exists, it typically involves higher melting points and different casting methods, whereas HPDC excels with lower melting point non-ferrous alloys.

- Melting and Holding: The chosen zinc alloy is melted in a furnace to a specific temperature (typically around 420-430°C for zinc alloys) and held in a heated reservoir to maintain consistency.

- Injection: The molten metal is then transferred to a shot chamber. A powerful hydraulic ram forces the molten metal at high pressure (up to 4500 psi or 300 bar) and high velocity into the pre-heated steel die cavity. This rapid injection ensures complete filling of intricate mold details.

- Solidification: Once injected, the molten metal rapidly cools and solidifies within the water-cooled die cavity. The high pressure is maintained during solidification to prevent shrinkage porosity, ensuring a dense and structurally sound component.

- Ejection: After solidification, the die opens, and ejector pins push the solid casting out of the mold. The die is then cleaned and lubricated in preparation for the next cycle, allowing for extremely high production rates.

- Trimming and Finishing: The ejected casting often includes a “flash” (excess material at the parting line) and runner systems. These are removed via trimming, machining, or grinding processes. Subsequent finishing operations can include deburring, tumbling, surface coating, or plating as per client specifications.

- Quality Control and Testing: Throughout the process, stringent quality control measures are implemented. This includes visual inspections, dimensional checks, mechanical property testing (hardness, tensile strength), and non-destructive testing (X-ray, ultrasonic) to ensure compliance with standards such as ISO 9001:2015 and ASTM B86.

Our adherence to these rigorous processes ensures an extended service life for our components, typically exceeding industry averages, and makes them suitable for demanding target industries like automotive, electronics, telecommunications, and industrial equipment. Our parts demonstrate significant advantages in typical application scenarios such as energy saving through lightweight design and superior corrosion resistance due to material selection and surface treatments.

Precision tooling is fundamental to intricate die casting production.

Technical Specifications: OEM Custom Zinc Die Casting

Zinc alloys are celebrated for their exceptional combination of strength, ductility, and castability, making them ideal for complex, high-precision components. The following table outlines typical specifications for our OEM Custom Zinc Die Casting products, highlighting the properties that make them suitable for diverse industrial applications.

| Parameter | Typical Specification (Zamak 3/Zamak 5) | Benefit in Application |

|---|---|---|

| Alloy Type | Zamak 3 (Zn-4Al-0.03Mg), Zamak 5 (Zn-4Al-1Cu-0.03Mg) | Zamak 3 for ductility, Zamak 5 for higher strength/hardness. |

| Tensile Strength | 283-324 MPa (Zamak 3), 324-380 MPa (Zamak 5) | High structural integrity for demanding mechanical loads. |

| Yield Strength | 207-220 MPa (Zamak 3), 260-310 MPa (Zamak 5) | Resistance to permanent deformation under stress. |

| Hardness (Brinell) | 82 HB (Zamak 3), 91 HB (Zamak 5) | Excellent wear resistance and surface durability. |

| Elongation (% in 2″) | 7-10% (Zamak 3), 2-4% (Zamak 5) | Ductility for post-casting forming or impact resistance. |

| Density | 6.7 g/cm³ | Relatively high density for robust components, yet excellent strength-to-weight for certain applications. |

| Melting Point | 385-387°C | Low melting point allows for longer die life and energy efficiency. |

| Tolerance Capability | +/- 0.05mm for first 25mm, +/- 0.002mm/mm thereafter (dependent on geometry) | High precision for complex assemblies, minimal post-machining. |

| Surface Finish | Very smooth (typically 0.8-3.2 Ra µm), ready for plating/coating | Aesthetically appealing, reduced finishing costs, excellent base for various coatings. |

These properties, combined with zinc’s inherent corrosion resistance and excellent thermal conductivity, make it a preferred choice for a wide array of precision applications. Compared to `aluminium die casting`, zinc offers superior strength and hardness in thinner walls, enabling miniaturization and weight reduction in specific contexts, and often a longer die life due to lower casting temperatures.

Application Scenarios and Technical Advantages

The versatility of zinc die casting makes it indispensable across numerous industries, each benefiting from its unique technical advantages:

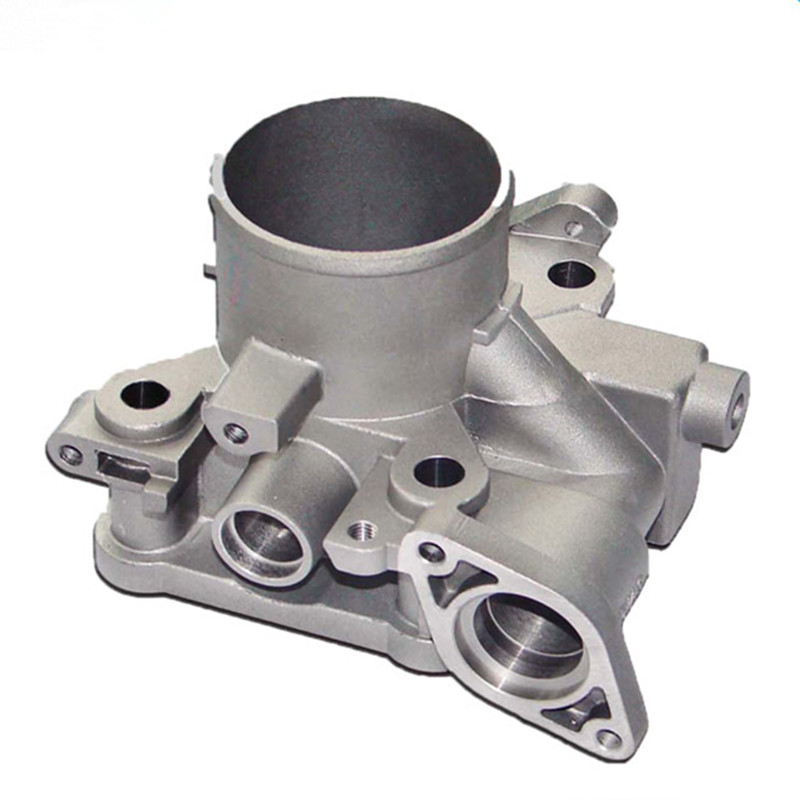

- Automotive Industry: From robust engine components (housings, throttle bodies) and transmission parts to intricate interior fittings and electronic enclosures. Zinc die castings contribute to lightweighting, enhanced corrosion resistance, and structural integrity, leading to improved fuel efficiency and vehicle longevity.

- Electronics and Telecommunications: Precision housings for smartphones, laptops, connectors, heat sinks, and EMI/RFI shielding components. Zinc alloys offer excellent electromagnetic shielding capabilities, ensuring device functionality and longevity while allowing for thin-wall, complex designs.

- Industrial Machinery and Equipment: Components for pumps, valves, power tools, and pneumatic equipment. The strength and wear resistance of zinc alloys ensure durable performance in demanding operational environments.

- Medical Devices: Housings for diagnostic equipment, surgical tool components, and other critical parts where precision, sterility, and durability are paramount. Zinc’s non-toxic nature and ability to achieve fine finishes are beneficial.

- Consumer Goods: Appliance parts, hardware, and decorative items that require a high-quality finish and complex shapes.

Beyond industry-specific applications, the general advantages of die casting include:

- Energy Saving: The ability to produce net-shape or near-net-shape components minimizes material waste and subsequent machining, reducing overall energy consumption in manufacturing. Lightweight zinc components also contribute to energy savings in end-use applications (e.g., automotive).

- Corrosion Resistance: Zinc alloys possess inherent resistance to corrosion, which can be further enhanced with various plating and coating options, extending product life in harsh environments.

- Exceptional Surface Finish: Parts emerge with smooth, uniform surfaces, ready for plating, painting, or polishing, reducing post-processing costs.

- High Dimensional Stability: Components maintain their precise dimensions over time and under varying environmental conditions.

- Rapid Production Rates: Ideal for high-volume production, offering excellent cost-efficiency per part.

Precision die-cast components are critical for industrial electronics.

Vendor Comparison and Selection Criteria

Selecting the right die casting partner is a strategic decision that directly impacts product quality, cost-efficiency, and time-to-market. When evaluating potential vendors for OEM Custom Zinc Die Casting, consider the following critical criteria:

- Technological Capability & Expertise: Assess the vendor’s machinery, software, and engineering team’s proficiency in advanced die casting techniques. Look for experience with complex geometries, tight tolerances, and various alloys.

- Quality Certifications & Compliance: Ensure the vendor holds relevant certifications such as ISO 9001:2015 (quality management), ISO 14001 (environmental management), and IATF 16949 (automotive quality management, if applicable). These demonstrate a commitment to rigorous quality standards.

- Experience and Track Record: Longevity in the industry (e.g., Mingda Metals’ years of service) and a portfolio of successful projects with reputable clients are strong indicators of reliability and expertise.

- Customization & Design Support: A strong vendor offers comprehensive DFM (Design for Manufacturability) support, assisting with alloy selection, mold design optimization, and prototyping to ensure the most efficient and effective solution.

- Production Capacity & Lead Times: Evaluate their ability to meet your required production volumes and adhere to agreed-upon lead times, which are crucial for supply chain stability.

- Cost-Effectiveness: While not the sole determinant, a competitive pricing structure coupled with value-added services (e.g., secondary operations, assembly) is essential.

- After-Sales Support & Warranty: A reputable vendor provides robust customer support, technical assistance, and clear warranty commitments, ensuring long-term partnership value.

Mingda Metals prides itself on exceeding these benchmarks, offering a blend of technical prowess, stringent quality control, and client-centric service to deliver unparalleled OEM Custom Zinc Die Casting solutions.

Customized Solutions in Die Casting

The strength of die casting lies not just in its efficiency but in its adaptability to highly specific requirements. Customized solutions are at the core of our B2B offering, ensuring that each component is perfectly tailored to its intended function. Our approach to customization includes:

- Collaborative Design for Manufacturability (DFM): Our engineers work closely with your design team from concept to final product, optimizing designs for cost-efficiency, castability, and performance. This includes detailed analysis of draft angles, wall thicknesses, gating, and venting to ensure the highest quality part.

- Alloy Selection Expertise: Guiding clients through the selection of the most appropriate zinc alloy (e.g., Zamak 2, 3, 5, 7, ZA-8) based on required mechanical properties, environmental resistance, and cost targets.

- Advanced Tooling Design and Fabrication: Developing highly durable and precise molds capable of producing millions of parts. Our in-house tooling capabilities ensure rapid prototyping and accurate, consistent production.

- Secondary Operations and Finishing: Providing a full suite of value-added services post-casting, including CNC machining for tighter tolerances, deburring, polishing, vibratory finishing, shot blasting, and various surface treatments like plating (nickel, chrome, zinc), powder coating, and painting.

- Assembly Services: Offering partial or full assembly of components, reducing your supply chain complexity and final assembly costs.

Custom tooling is developed for unique die casting requirements.

Application Case Studies: Delivering Real-World Value

Our track record of successful projects demonstrates our commitment to engineering excellence and client satisfaction. Here are examples showcasing the impact of our OEM Custom Zinc Die Casting solutions:

Case Study 1: High-Performance Automotive Sensor Housing

Client Challenge: An automotive Tier 1 supplier needed a sensor housing that was extremely durable, capable of precise heat dissipation, and could withstand harsh under-hood environments, including exposure to fuels and vibrations, while meeting strict lightweighting targets. Traditional machined aluminum parts were too costly and heavy for high-volume production.

Mingda Metals Solution: We collaborated with the client on a DFM review, recommending Zamak 5 for its superior strength and hardness. Our advanced die casting process enabled the production of a thin-walled, intricate housing with integrated heat sinks and mounting features, maintaining tight tolerances (±0.05mm). Post-casting, a specialized chemical conversion coating was applied for enhanced corrosion resistance.

Results: The zinc die-cast housing achieved a 15% weight reduction compared to the previous aluminum design, significantly reduced unit costs through high-speed production, and passed all automotive environmental and vibration tests. The thermal management properties were also markedly improved, leading to extended sensor lifespan.

Case Study 2: Medical Device Enclosure for Portable Diagnostics

Client Challenge: A medical device manufacturer required a compact, aesthetically pleasing, and robust enclosure for a new portable diagnostic unit. The enclosure needed excellent EMI/RFI shielding to protect sensitive internal electronics, a smooth surface for easy sterilization, and rapid production capabilities to meet market demand.

Mingda Metals Solution: Utilizing Zamak 3, known for its excellent castability and fine surface finish, we designed and produced the complex enclosure with integrated shielding features. Our precise die casting ensured consistent wall thickness for optimal shielding and a high-quality surface that was easily powder-coated for sterilization and aesthetic appeal.

Results: The client received a highly functional enclosure that met all regulatory requirements for EMI/RFI shielding and sterilization. The smooth, seamless finish enhanced the device’s professional appearance, and our efficient production allowed the client to rapidly scale manufacturing, securing a strong market position.

Trustworthiness and Commitment to Excellence

Building trust in B2B partnerships is paramount. Mingda Metals upholds the highest standards of quality, reliability, and customer service.

Certifications and Authoritative References

Our commitment to quality is underscored by our adherence to international standards:

- ISO 9001:2015 Certified: Demonstrating a robust quality management system across all operations.

- Material Certifications: All raw materials are sourced from approved suppliers and come with certified material test reports, ensuring compliance with ASTM and relevant industry standards.

- Partner Clients: We serve a diverse global client base, including leaders in automotive, electronics, and industrial sectors, many of whom have been long-term partners for over a decade.

Frequently Asked Questions (FAQ)

Q: What is the typical lead time for a custom die casting project?

A: Lead times vary based on complexity. For tooling, it’s typically 4-8 weeks. Initial sample production (T1) takes another 2-3 weeks. Once samples are approved, mass production can begin within 1-2 weeks, with subsequent shipments adhering to an agreed schedule.

Q: What quality control measures are in place?

A: We implement multi-stage QC, including DFM analysis, first article inspection (FAI), in-process inspections using CMM and other metrology tools, and final inspection before shipment. All processes are documented and traceable per ISO 9001 standards.

Q: Can you assist with design optimization for die casting?

A: Absolutely. Our engineering team provides comprehensive DFM services, leveraging advanced simulation software to optimize part design for castability, material efficiency, and performance, ensuring the most cost-effective and highest-quality outcome.

Q: What alloys do you work with for die casting?

A: Our specialization is primarily in zinc alloys (Zamak series: 2, 3, 5, 7, ZA-8). We also have capabilities for `aluminium die casting` and other non-ferrous alloys based on project requirements.

Warranty and Customer Support

Mingda Metals stands behind the quality of its products. We offer a comprehensive warranty on all components, covering material defects and manufacturing errors. Our dedicated customer support team and technical engineers are available to assist with any inquiries, from initial design consultation to post-delivery support, ensuring a seamless and reliable partnership.

Rigorous quality control ensures precision in every die casting.

Conclusion: Partnering for Die Casting Excellence

The demand for precision metal components continues to drive innovation in the die casting industry. With its ability to produce highly complex, strong, and durable parts efficiently, die casting remains a cornerstone of modern manufacturing. Mingda Metals offers comprehensive OEM Custom Zinc Die Casting services, combining cutting-edge technology, deep engineering expertise, and an unwavering commitment to quality and customer satisfaction. Partner with us to transform your designs into high-performance realities.

References

- ASM Handbook Volume 15: Casting. ASM International, 2008.

- NADCA (North American Die Casting Association) – Die Casting Designer’s Guide.

- “Zinc Die Casting: A Practical Guide.” International Zinc Association.

- ISO 9001:2015 – Quality management systems — Requirements.

- ASTM B86 / B86M − 20, Standard Specification for Zinc and Zinc-Aluminum (ZA) Alloy Foundry and Die Castings.

Hebei Mingda International Trading Company is a trading company which is specialized in castings, ODM Ductile Iron Manhole Cover forgings and machinery parts.Our products include all kinds of raw castings to be made of ductile iron , grey iron , brass , stainless steel and aluminums, machined castings and forged parts .ODM Ductile Iron Covers To make these parts according to the customers’Custom Iron Casting drawings , we have relative suitable production craft and equipments, such as resin sand , sand mould , hot core boxes , lost-wax , lost –foam and so on Iron Casting Manufacturer Custom.Specially for hydrant bodies and valves’Ductile Iron Manhole Cover Manufacturer bodies, we have collected rich experience for these products in the past 16 year’s actual production, Now we are proud of our products with good surface and high quality material. Iron Casting ManufacturerWhatever,we have been trying our best to provide our customers with better quality castings by improving production crafts and more careful quality control.Cast Iron Castings Manufacturer|super blog