Composite manhole covers: an insider’s field note from the streets and the shop floor

If you’ve ever spec’d access hardware for utilities or roads, you know the hidden drama underfoot. City engineers call me when metals rattle, corrode, or worse—disappear for scrap. That’s why manhole covers made from BMC/SMC composites have quietly become the hero of modern infrastructure. To be honest, the shift felt slow at first. Now it’s accelerating, and for good reasons: safety, lifecycle cost, and ESG pressure.

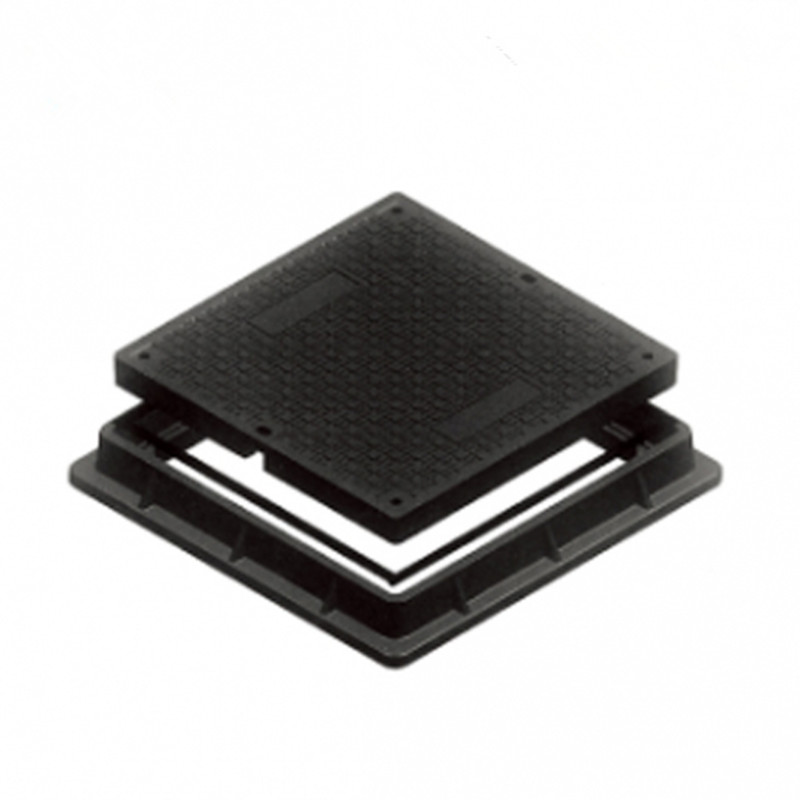

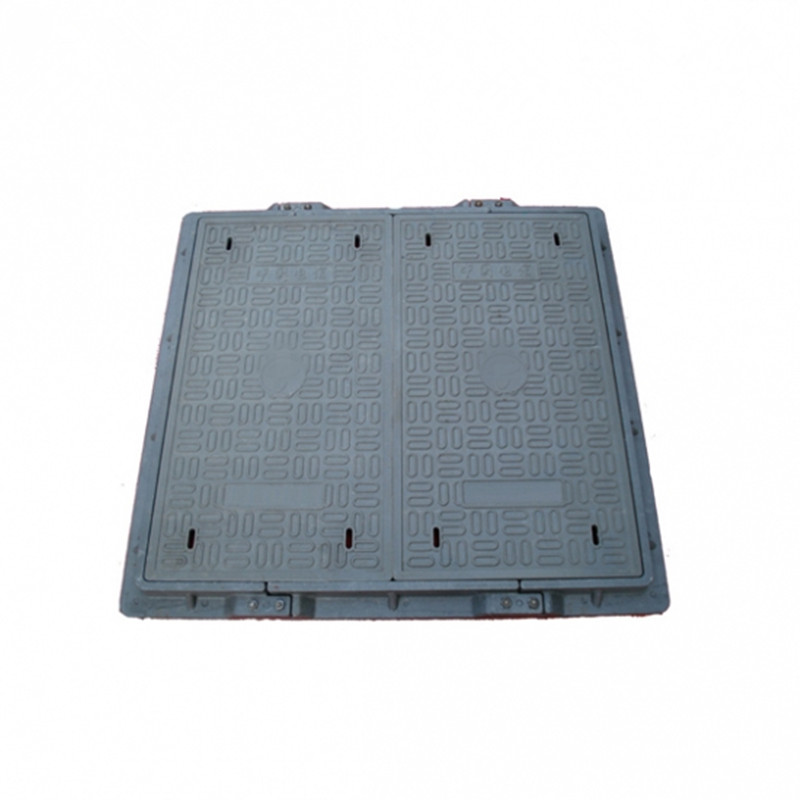

Product snapshot: BMC SMC Composite Manhole Cover and Frame (Mingda-0004)

Origin: Gelan Building, No.256 Xisanzhuang Street, Shijiazhuang, Hebei, China. Certification: SGS, ISO 9001:2008. Packaging: standard export package. Productivity ≈ 100 Ton/Month. Brand: Mingda. Model No.: Mingda-0004. Many customers say the weight-to-strength ratio is the clincher; crews love the ergonomics.

| Material System | BMC/SMC (unsaturated polyester resin + fiberglass), resin sand core in tooling |

| Typical Load Classes | EN 124 A15–D400 (real-world selection depends on site category) |

| Flexural Strength | ≈ 150–200 MPa (ISO 178) |

| Water Absorption | |

| UV/Weathering | Accelerated exposure passed (ISO 4892-2), color shift minimal |

| Electrical Properties | Non-conductive—useful for power/telecom vaults |

| Service Life | Designed for 25–35+ years, depending on traffic and chemistry |

Process flow (shop-floor version)

- Materials: SMC/BMC compounded with chopped glass, fillers, pigment; resin sand core for mold stability.

- Compression molding: preform charge → heated steel mold (≈140–160°C) → pressure 80–120 bar → cure.

- Finishing: demold, CNC trim, anti-skid texture, logo plate, optional locking hardware.

- Testing: static load per EN 124-1/-5; flexural (ISO 178); impact (ISO 179); slip resistance (pendulum test); water absorption (ASTM D570); chemical resistance (ASTM D543); thermal cycling.

- QC sign-off: traceability code, dimensional check, frame-seat flatness.

Where they shine (applications)

Urban streets (B125–D400), sidewalks/parks (A15–B125), wastewater and stormwater networks, power substations (non-conductive), telecom pits, coastal ports where corrosion eats metal. Surprisingly, noise complaints drop—composites don’t clang. Most stakeholders switch to manhole covers like these for theft resistance (no scrap value) and easier handling.

Advantages I keep seeing

- Lighter installs: fewer crew injuries; faster night work.

- Corrosion and chemical resistance: great for saline or acidic soils.

- Branding: molded logos, QR/serials for digital asset management.

- Lifecycle economics: fewer replacements; less rattle-related maintenance.

| Vendor | Material | Certs | Lead Time | MOQ | Notes / ≈Price |

|---|---|---|---|---|---|

| Mingda (Mingda-0004) | BMC/SMC composite | SGS, ISO 9001:2008 | ≈ 3–5 weeks | Project-based | Competitive; customizable logo/locking |

| Cast-iron supplier (generic) | Gray/ductile iron | EN 124-2; ISO 9001 | 4–8 weeks | Higher | Strong, but theft/corrosion risks; heavier |

| Polymer concrete brand | Polymer concrete | EN 124-1/-6 | ≈ 5–7 weeks | Medium | Rigid; good chemical resistance; weight varies |

Customization and real projects

Options: color matching, embossed logos, vent/solid lids, anti-slip patterns, stainless hinges, bolt-down/triangular locks, RFID tags. One Southeast Asian city swapped 600 manhole covers on bus corridors for D400 composites—zero thefts after 12 months, and crews cut average replacement time by roughly 35%. A telecom client added insulating lids over fiber chambers; they told me their shock-risk notices dropped to… basically none.

If you’re benchmarking manhole covers right now, ask for recent EN 124 load test reports and UV/chemical data. Actually, I’d also check frame-seat tolerances; that’s where rattles start. Mingda ships from Hebei with standard export packaging, and in my notes their QA traceability is tidy.

Authoritative references

- EN 124-1:2015, Gully tops and manhole tops for vehicular and pedestrian areas—General requirements.

- EN 124-5:2015, Manhole tops and gully tops made of composite materials—Requirements and testing.

- ISO 178, Plastics—Determination of flexural properties.

- ISO 179, Plastics—Charpy impact properties.

- ISO 4892-2, Plastics—Artificial weathering—Xenon-arc exposure.

- ASTM D543/D570, Chemical resistance and water absorption of plastics.

Hebei Mingda International Trading Company is a trading company which is specialized in castings, ODM Ductile Iron Manhole Cover forgings and machinery parts.Our products include all kinds of raw castings to be made of ductile iron , grey iron , brass , stainless steel and aluminums, machined castings and forged parts .ODM Ductile Iron Covers To make these parts according to the customers’Custom Iron Casting drawings , we have relative suitable production craft and equipments, such as resin sand , sand mould , hot core boxes , lost-wax , lost –foam and so on Iron Casting Manufacturer Custom.Specially for hydrant bodies and valves’Ductile Iron Manhole Cover Manufacturer bodies, we have collected rich experience for these products in the past 16 year’s actual production, Now we are proud of our products with good surface and high quality material. Iron Casting ManufacturerWhatever,we have been trying our best to provide our customers with better quality castings by improving production crafts and more careful quality control.Cast Iron Castings Manufacturer|super blog