What Manufacturers Really Need to Know About lost wax casting in 2025

If you’re speccing stainless parts for machinery—and you want near-net shapes without a machining hangover—this process keeps popping up. To be honest, it’s having a bit of a moment. Between reshoring pressures, tighter tolerances, and the push for corrosion-proof hardware, lost wax casting is quietly replacing old-school sand cast and even some billet machining programs.

Why the buzz now?

- Miniaturization + complexity: thin walls, undercuts, fine lettering—no drama.

- Digital tooling: printed patterns reduce lead time and tweak costs.

- Surface finish: Ra ≈ 6.3 μm out of the shell, polishing pushes it further.

- Sustainability: higher yield, less chip waste than billet machining.

Process flow (real-world, not brochure-ware)

Typical stainless program for machinery parts runs like this: wax injection (pressure-injected patterns), treeing, ceramic shell build (slurry + stucco cycles), dewax (autoclave), shell firing, thermal gravity pour, knockout, cut-off, heat treatment, CNC finish where needed, polishing/passivation (ASTM A967), and final inspection. Dimensional checks usually map to ISO 8062-3 CT6–CT7; functional faces are machined to ±0.01 mm when needed. NDT is often PT (ASTM E1417) and spot RT for safety-critical features.

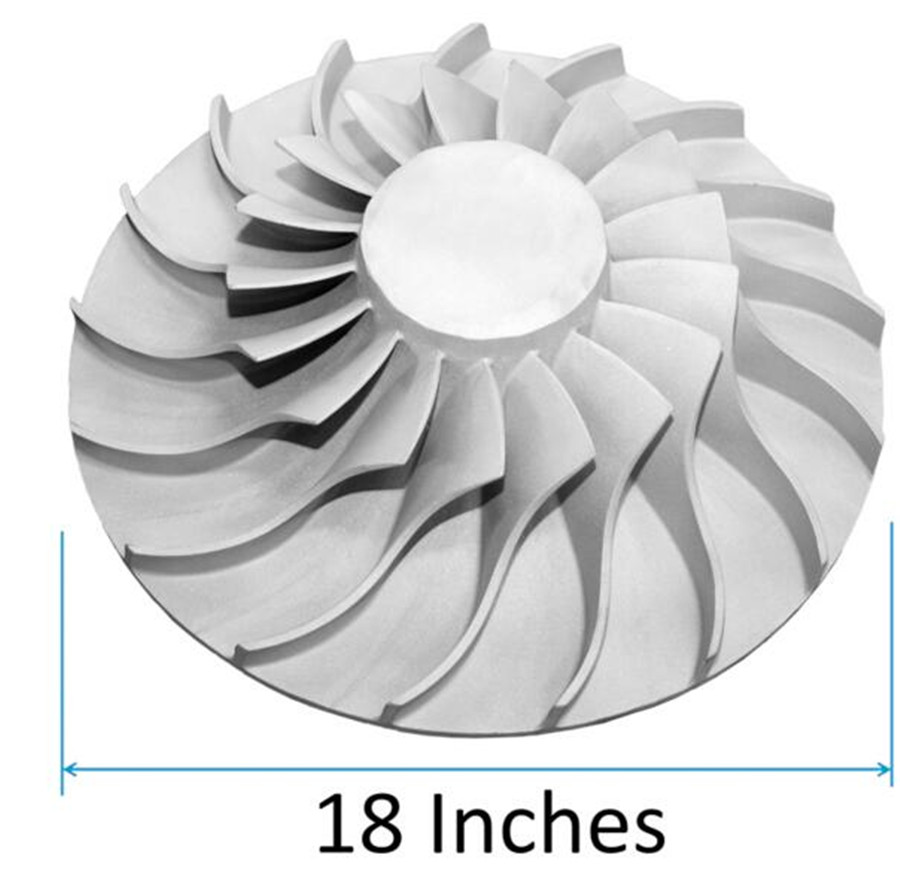

Product snapshot: Stainless Lost Wax Casting for Machinery Part

| Attribute | Spec (≈ real-world) |

|---|---|

| Process | lost wax casting, thermal gravity pour; wax injection molds |

| Material | Stainless (304/316/CF8/CF8M per ASTM A743/A744) |

| Surface roughness | Ra ≈ 6.3 μm as-cast; finer with polishing |

| Tolerance | As-cast to ISO 8062-3 CT6–CT7; machined ±0.01 mm |

| Surface prep | Polishing, passivation (ASTM A967), optional electropolish |

| Typical tensile (316/CF8M) | ≈ 485 MPa UTS; ≈ 170 MPa YS (heat treatment dependent) |

| Applications | Pumps/valves, conveyors, food equipment, marine hardware |

Where it works best

If you’re chasing corrosion resistance plus tidy geometry, this shines in pumps/valves, bottling and pharma handling (304/316 with passivation), and marine brackets. In many conveyor subsystems we see service life of 5–10 years, sometimes longer, assuming routine cleaning and no abrasive slurry exposure. Many customers say the maintenance delta versus welded fabrications is noticeable after year two.

Vendor comparison (quick reality check)

| Vendor | Certs | Lead Time | As-cast Tolerance | NDT | Notes |

|---|---|---|---|---|---|

| MingDa Metals (Shijiazhuang, Hebei) | ISO 9001; EN 10204 3.1 material certs | ≈ 4–6 wks tooling; 2–4 wks production | ISO 8062-3 CT6–CT7 | PT standard; RT on request | Strong on stainless polish/passivation |

| Vendor B | ISO 9001, IATF 16949 | 6–8 wks | CT7–CT8 | PT/UT | Good APQP docs, pricier |

| Vendor C | ISO 9001 | 3–5 wks | CT7 | PT | Fast quotes; limited stainless grades |

Customization, QC, and what buyers ask me all the time

- Design for lost wax casting: add uniform wall sections (2.5–6 mm), soft transitions, and casting radii (≥ 0.5 mm) to keep shells happy.

- Testing: PT (ASTM E1417), occasional RT; mechanicals to ASTM A370; corrosion checks per service (salt spray ASTM B117 for reference).

- Traceability: EN 10204 3.1 heat certs, lot-level SPC; capability targets Cpk ≥ 1.33 on CTQs.

Case study 1: 316L pump rotor, 11% weight reduction via topology tweaks; as-cast CT6, final bores to ±0.01 mm, service life projected 7–10 yrs in brackish water. Case study 2: 304 hanger bracket for a bottling line—polished and passivated; downtime cut by 18% per maintenance logs, which surprised even the line chief.

Practical buying notes

FOB from Gelan Building, No.256 Xisanzhuang Street, Shijiazhuang, Hebei, China. For recurring programs, lock a master gauge and PPAP-lite (even outside automotive) to stabilize revisions. And yes, DFM feedback early saves weeks—ask for shell simulations and gate/risers review before freezing tooling.

Citations

- ISO 8062-3: Geometrical product specifications—Dimensional and geometrical tolerances for castings.

- ASTM E1417/E1417M: Standard Practice for Liquid Penetrant Testing.

- ASTM A743/A744: Standard Specifications for Castings, Iron-Chromium, Iron-Chromium-Nickel.

- ASTM A967: Standard Specification for Chemical Passivation Treatments for Stainless Steel Parts.

- ISO 9001:2015; IATF 16949:2016—Quality management systems.

- EN 10204 3.1: Metallic products—Types of inspection documents.

Hebei Mingda International Trading Company is a trading company which is specialized in castings, ODM Ductile Iron Manhole Cover forgings and machinery parts.Our products include all kinds of raw castings to be made of ductile iron , grey iron , brass , stainless steel and aluminums, machined castings and forged parts .ODM Ductile Iron Covers To make these parts according to the customers’Custom Iron Casting drawings , we have relative suitable production craft and equipments, such as resin sand , sand mould , hot core boxes , lost-wax , lost –foam and so on Iron Casting Manufacturer Custom.Specially for hydrant bodies and valves’Ductile Iron Manhole Cover Manufacturer bodies, we have collected rich experience for these products in the past 16 year’s actual production, Now we are proud of our products with good surface and high quality material. Iron Casting ManufacturerWhatever,we have been trying our best to provide our customers with better quality castings by improving production crafts and more careful quality control.Cast Iron Castings Manufacturer|super blog