Understanding Carbon Steel Flanges: An Essential Component in Industrial Piping

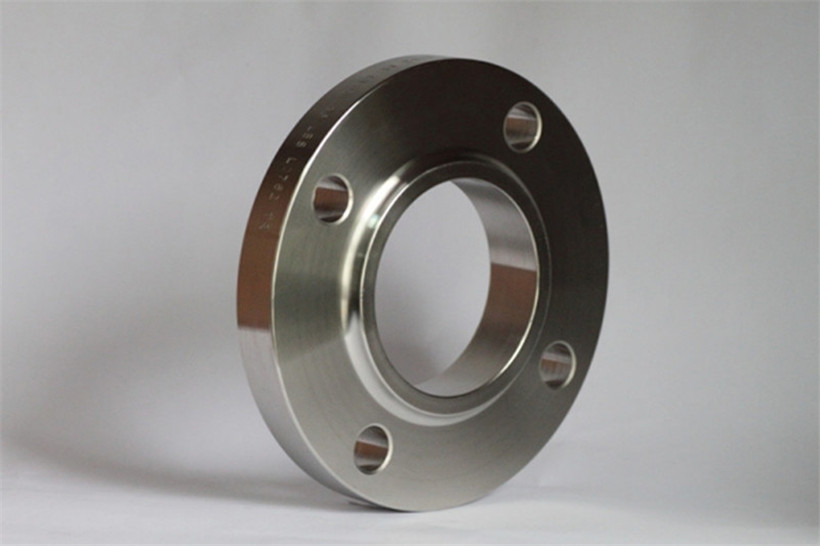

In industrial piping systems, a critical component ensuring robust, leak-free connections is the carbon steel flange. These mechanical connectors are indispensable across a multitude of heavy industries, facilitating the assembly and disassembly of piping, valves, pumps, and other equipment. Their reliability under pressure and temperature variations makes them a go-to choice for engineers and procurement specialists globally. This comprehensive guide delves into the technical intricacies, market dynamics, and operational advantages of carbon steel flanges, providing B2B decision-makers with the insights needed for informed purchasing and application.

Current Industry Trends and Market Dynamics

The market for industrial flanges, particularly for carbon steel flange products, is experiencing steady growth driven by global infrastructure development, increasing energy demands, and expansion in sectors like oil & gas, power generation, and chemical processing. Key trends shaping this market include:

- Demand for Higher Pressure and Temperature Ratings: Advancements in industrial processes necessitate flanges capable of withstanding more extreme operating conditions, pushing manufacturers to innovate in material science and forging techniques.

- Emphasis on Sustainability and Efficiency: There’s a growing push for products that contribute to energy saving and have extended service lives, reducing replacement frequency and environmental impact. This includes optimizing manufacturing processes to reduce waste and energy consumption.

- Digitalization and Automation: The adoption of smart manufacturing, including automated CNC machining and advanced quality control systems, is enhancing precision, reducing human error, and improving production efficiency in the steel flange factory.

- Global Supply Chain Diversification: Geopolitical factors and trade dynamics are leading to a more diversified supply chain, with companies seeking reliable partners across different regions to mitigate risks.

- Rise of Customized Solutions: As projects become more specialized, the demand for tailored flange designs that meet unique operational parameters, material requirements, and structural integrations is increasing.

These trends highlight a market that values not only robust construction but also precision engineering, adherence to stringent standards, and the ability to offer flexible, high-performance solutions.

Detailed Manufacturing Process Flow of Carbon Steel Flanges

The production of a high-quality carbon steel flange involves several meticulously controlled stages to ensure durability, dimensional accuracy, and compliance with international standards. Here’s a typical process flow:

-

Material Selection & Preparation:

The process begins with selecting high-grade carbon steel, typically specified by ASTM A105 (for forged) or ASTM A216 WCB (for cast) standards, depending on the required mechanical properties and application. Raw material, often in the form of billets or plates, is cut to appropriate sizes.

-

Heating & Forging/Casting:

Forging: Forged flanges (e.g., weld neck steel flange) are produced by heating steel billets to a plastic state (typically 1100-1200°C) and then shaping them using powerful presses or hammers. This process refines the grain structure, enhancing strength and toughness.

Casting: For cast carbon steel flange products, molten carbon steel is poured into a mold designed to the flange’s specifications. While generally less strong than forged flanges, casting allows for more complex geometries and can be cost-effective for certain applications.

-

Heat Treatment:

After forging or casting, flanges undergo heat treatment processes like normalizing, annealing, or tempering. This critical step relieves internal stresses, improves ductility, refines grain structure, and ensures the material achieves its optimal mechanical properties, contributing significantly to its service life.

-

Machining & Drilling:

Precision CNC machining is employed to achieve the exact dimensions, surface finish, and bolt hole patterns required by standards such as ASME B16.5 or ASME B16.47. This includes facing, boring, and drilling operations, ensuring accurate fit-up and leak-proof sealing.

-

Surface Treatment & Coating:

To enhance corrosion resistance and extend service life, flanges may undergo surface treatments such as shot blasting, anti-rust oil application, painting, or galvanizing, especially for flanges used in harsh environments.

-

Quality Control & Testing:

Each flange undergoes rigorous testing. This includes dimensional inspection, visual inspection for defects, material composition analysis (e.g., Spectro analysis), mechanical property testing (tensile, impact, hardness), and Non-Destructive Testing (NDT) like Ultrasonic Testing (UT) or Magnetic Particle Inspection (MPI) to detect internal flaws. Pressure testing may also be performed to verify integrity. These tests ensure compliance with ISO, ANSI, ASTM, and other relevant international standards, affirming the product’s reliability and performance in target industries such as petrochemical, metallurgy, and water supply & drainage.

-

Marking & Packaging:

Finally, flanges are marked with essential information (material grade, size, pressure class, manufacturer’s logo) and carefully packaged to prevent damage during transit.

Technical Specifications and International Standards

Adherence to international technical specifications is paramount for ensuring the interoperability, safety, and performance of asme carbon steel flange products in complex industrial systems. Key standards include:

- ASME B16.5: Covers pipe flanges and flanged fittings for NPS 1/2 through NPS 24. It specifies dimensions, tolerances, materials, pressure-temperature ratings, marking, and testing.

- ASME B16.47: Addresses large diameter steel flanges (NPS 26 through NPS 60) in two series, A and B, which define pressure-temperature ratings, materials, dimensions, tolerances, marking, and testing.

- ASTM A105/A105M: Standard Specification for Forgings, Carbon Steel, for Piping Components. This is a common material specification for forged carbon steel flanges.

- ASTM A216/A216M: Standard Specification for Steel Castings, Carbon, Suitable for Fusion Welding, for High-Temperature Service. This applies to cast carbon steel flanges.

- ISO 9001: Quality Management Systems standard, indicating a manufacturer’s commitment to consistent quality.

Typical Carbon Steel Flange Specifications (ASME B16.5 Example)

| Parameter | Specification/Value | Notes |

|---|---|---|

| Material Grade | ASTM A105 (Forged Carbon Steel) | Common for pressure piping |

| Pressure Class | Class 150, 300, 600, 900, 1500, 2500 | Corresponds to maximum allowable pressure at specific temperatures |

| Standard Size Range | NPS 1/2″ to 24″ (ASME B16.5) | Larger sizes under ASME B16.47 |

| Face Type | Raised Face (RF), Flat Face (FF), Ring Type Joint (RTJ) | Determines gasket and sealing method |

| Manufacturing Method | Forged or Cast | Forged offers superior strength |

| Typical Tensile Strength (A105) | Min 70 ksi (485 MPa) | Resistance to breaking under tension |

| Typical Yield Strength (A105) | Min 36 ksi (250 MPa) | Resistance to permanent deformation |

Diverse Application Scenarios

The versatility and robust nature of carbon steel flange components make them indispensable across a broad spectrum of industrial applications. Their ability to handle high pressures and temperatures, combined with their cost-effectiveness, drives their widespread adoption.

- Petrochemical Industry: Used extensively in oil refineries, chemical plants, and natural gas processing facilities for connecting pipes carrying crude oil, refined products, chemicals, and gases under high pressure and temperature.

- Power Generation: Crucial in thermal, nuclear, and hydroelectric power plants for steam lines, cooling water systems, and fuel supply lines. The ability to withstand high-temperature steam is particularly vital.

- Water Supply & Drainage: Employed in municipal water treatment plants, pumping stations, and large-scale irrigation systems to connect pipelines that transport water, often under significant pressure.

- Metallurgy & Mining: Used in mineral processing plants and smelters where heavy-duty piping systems transport slurries, water, and process fluids.

- Shipbuilding & Marine: Integrated into ship piping systems for fuel, ballast, and cooling water lines, where durability and resistance to harsh marine conditions are essential.

- HVAC Systems: In large commercial and industrial heating, ventilation, and air conditioning systems for chiller lines and hot water piping.

In these scenarios, the proper selection of flange type (e.g., slip-on, blind, socket weld, or weld neck steel flange) and pressure class is critical to ensure operational safety, system efficiency, and long-term reliability.

Technical Advantages of Carbon Steel Flanges

Choosing carbon steel flange components offers a range of significant technical and operational advantages for industrial applications:

- High Strength and Durability: Carbon steel provides excellent tensile and yield strength, allowing flanges to withstand high pressures and mechanical stresses without deformation or failure. This translates to a longer service life and reduced maintenance.

- Temperature Resistance: Capable of performing reliably across a wide temperature range, from sub-zero conditions to elevated temperatures (up to approximately 425°C or 800°F, depending on pressure class and specific grade), making them suitable for diverse thermal applications.

- Cost-Effectiveness: Compared to more exotic alloys, carbon steel offers a superior strength-to-cost ratio, making it an economically viable option for large-scale projects without compromising on structural integrity.

- Excellent Weldability: Most carbon steel grades are readily weldable, simplifying installation and allowing for robust, permanent connections, particularly for weld neck and socket weld flanges.

- Standardization: Widely standardized under ASME, API, and ISO, ensuring interchangeability, ease of procurement, and consistent quality across manufacturers.

- Energy Saving through Optimal Sealing: When paired with appropriate gaskets and installed correctly, high-quality flanges provide an exceptionally tight seal, minimizing leaks and preventing energy loss in fluid or gas transport systems. This contributes to operational efficiency and compliance with environmental regulations.

While basic carbon steel offers limited corrosion resistance, this can be effectively mitigated through appropriate coatings, galvanizing, or cathodic protection, extending their applicability to moderately corrosive environments.

Vendor Comparison and Customized Solutions

Selecting the right supplier for carbon steel flange products is a critical decision that impacts project timelines, costs, and long-term system reliability. Key factors for vendor comparison include manufacturing capabilities, quality control protocols, certifications, lead times, and the ability to provide customized solutions.

Comparison: Standard vs. Premium Flange Manufacturers

| Feature | Standard Manufacturer | Premium Manufacturer (e.g., Specialized Flange Factory) |

|---|---|---|

| Material Sourcing | Often varied, may prioritize cost over consistent origin. | Certified mills, traceable batches, guaranteed composition. |

| Manufacturing Process | Batch production, basic machining, less stringent heat treatment. | Advanced forging, precision CNC, controlled atmosphere heat treatment. |

| Quality Control | Basic dimensional checks, minimal NDT. | Extensive NDT (UT, MPI), material certification, third-party inspection. |

| Certifications | Basic ISO 9001, perhaps material certificates. | ISO 9001, PED, AD 2000, API Q1, specific end-user approvals. |

| Customization | Limited to standard modifications (e.g., facing type). | Full engineering support, bespoke designs, special drilling, overlay cladding. |

| Lead Time/Flexibility | Standard lead times, less flexible for urgent orders. | Potentially shorter lead times for common items, more agile for custom/urgent. |

Customized Solutions

For projects with unique requirements, standard off-the-shelf flanges may not suffice. Experienced manufacturers offer tailored solutions, which can include:

- Non-Standard Dimensions: Custom bore sizes, bolt circle diameters, or overall flange diameters.

- Special Materials: While the focus is on carbon steel, customization can extend to specific carbon steel alloys with enhanced properties (e.g., low-temperature carbon steel for cryogenic service).

- Unique Facing Options: Specialized gasket contact surfaces beyond RF, FF, or RTJ for specific sealing challenges.

- Integrated Components: Flanges with welded-on stubs, thermowell connections, or other integral features.

- Enhanced Surface Treatments: Customized coatings for aggressive corrosive environments or specific aesthetic requirements.

A reliable steel flange factory should possess the engineering expertise and manufacturing flexibility to collaborate closely with clients, from initial design consultation to final product delivery, ensuring that customized flanges integrate seamlessly into complex systems.

Application Case Studies

Real-world applications underscore the critical role and reliable performance of carbon steel flanges.

Case Study 1: High-Pressure Gas Pipeline Expansion

A major energy company undertook a significant expansion of its natural gas transmission pipeline network. The project required thousands of ASME carbon steel flange units, primarily Class 600 and Class 900 weld neck flanges, ranging from NPS 10 to NPS 36. The challenge was to source flanges capable of consistent performance under fluctuating high pressures and varying environmental temperatures across diverse terrains.

Our partnered supplier provided ASTM A105 forged carbon steel flanges, subjected to comprehensive ultrasonic testing (UT) and magnetic particle inspection (MPI) to ensure internal integrity and surface flaw detection. The flanges were supplied with an anti-corrosion coating suitable for buried applications. The rigorous quality control and on-time delivery prevented project delays, ensuring a robust, leak-free system that passed all hydrostatic testing with zero incidents, validating the supplier’s commitment to quality and expertise.

Case Study 2: Water Treatment Plant Upgrade

A municipal water treatment facility initiated an upgrade to its primary pumping and filtration systems. This involved replacing aged cast iron piping with new carbon steel lines to improve flow efficiency and system longevity. For this project, a mix of cast carbon steel flange and slip-on carbon steel flanges (Class 150 and 300) were specified for various sections of the plant’s water distribution and chemical dosing systems.

The selected vendor provided flanges manufactured to ASTM A216 WCB for cast and ASTM A105 for forged, ensuring compliance with drinking water safety standards where applicable. Customer feedback highlighted the consistent dimensional accuracy, which greatly eased installation, and the robust construction, which has contributed to significantly reduced maintenance costs and extended the expected service life of the modernized infrastructure. The project demonstrated the supplier’s capability in managing diverse flange requirements within a critical public utility context.

Authoritativeness and Trustworthiness: Our Commitment

Our dedication to quality and customer satisfaction is built on a foundation of recognized certifications, transparent processes, and unwavering support.

Certifications and Compliance

- ISO 9001:2015 Certified: Our quality management system adheres to the highest international standards, ensuring consistent product quality and process efficiency.

- PED (Pressure Equipment Directive) 2014/68/EU Compliant: All flanges destined for the European market comply with stringent safety requirements.

- Traceability: Full material traceability from raw material procurement to finished product, allowing for complete transparency and verification.

- Experienced Professionals: Our team comprises engineers and technicians with decades of experience in flange manufacturing and application, capable of handling complex project specifications.

Frequently Asked Questions (FAQ)

- Q: What is the typical lead time for a standard carbon steel flange order?

- A: For standard inventory items, lead times can be as short as 3-5 business days. For larger custom orders or specialized specifications, lead times generally range from 2-4 weeks, depending on complexity and quantity. We always provide an estimated delivery schedule upon order confirmation.

- Q: Do you provide material test certificates?

- A: Yes, every order is accompanied by a Mill Test Certificate (MTC) compliant with EN 10204 3.1, detailing the chemical composition and mechanical properties of the specific batch of material used.

- Q: What is your warranty policy for carbon steel flanges?

- A: We offer a standard 12-month warranty against manufacturing defects from the date of shipment. Our commitment is to provide products free from defects in material and workmanship under normal use and service.

- Q: Can you accommodate rush orders?

- A: We understand that project timelines can be tight. Depending on our production schedule and material availability, we can often accommodate rush orders for a premium. Please contact our sales team to discuss your urgent requirements.

After-Sales Support

Our commitment extends beyond delivery. We provide comprehensive after-sales support, including technical assistance for installation queries, troubleshooting, and guidance on optimal maintenance practices to maximize the service life of your flanges. Our dedicated customer service team is available to address any concerns promptly and efficiently. We believe strong client relationships are built on trust and reliable post-purchase service.

Conclusion

The carbon steel flange remains a foundational component in industrial infrastructure, valued for its strength, reliability, and cost-effectiveness. As industries evolve, so does the demand for higher performance, greater precision, and more specialized solutions. Partnering with a manufacturer that combines deep technical expertise with a commitment to stringent quality control and customer-centric service is crucial for ensuring the long-term success and safety of any piping system. By understanding the manufacturing process, adhering to international standards, and leveraging advanced data visualization, industries can confidently specify and deploy carbon steel flanges that meet the rigorous demands of modern operations.

References

- ASME B16.5-2020: Pipe Flanges and Flanged Fittings NPS 1/2 Through NPS 24 Metric/Inch Standard. American Society of Mechanical Engineers.

- ASTM A105/A105M-21: Standard Specification for Forgings, Carbon Steel, for Piping Components. ASTM International.

- ISO 9001:2015: Quality management systems — Requirements. International Organization for Standardization.

- PED 2014/68/EU: Pressure Equipment Directive. Official Journal of the European Union.

- Pipe Flanges: An Introduction to Design, Selection, and Application. John Smith, Industrial Piping Journal, Vol. 45, No. 3, 2018.

Hebei Mingda International Trading Company is a trading company which is specialized in castings, ODM Ductile Iron Manhole Cover forgings and machinery parts.Our products include all kinds of raw castings to be made of ductile iron , grey iron , brass , stainless steel and aluminums, machined castings and forged parts .ODM Ductile Iron Covers To make these parts according to the customers’Custom Iron Casting drawings , we have relative suitable production craft and equipments, such as resin sand , sand mould , hot core boxes , lost-wax , lost –foam and so on Iron Casting Manufacturer Custom.Specially for hydrant bodies and valves’Ductile Iron Manhole Cover Manufacturer bodies, we have collected rich experience for these products in the past 16 year’s actual production, Now we are proud of our products with good surface and high quality material. Iron Casting ManufacturerWhatever,we have been trying our best to provide our customers with better quality castings by improving production crafts and more careful quality control.Cast Iron Castings Manufacturer|super blog