Navigating the Landscape of Carbon Steel Flanges

In critical industrial applications, the integrity and reliability of piping systems are paramount. Flanges play a pivotal role in ensuring secure and leak-proof connections, and among the diverse range of materials, carbon steel stands out for its robust mechanical properties and cost-effectiveness. This article delves into the intricacies of china carbon steel flange, exploring its market dynamics, technical specifications, manufacturing processes, and application advantages, especially for B2B decision-makers seeking reliable and high-performance solutions.

The global demand for industrial components continues to grow, with China emerging as a dominant force in the manufacturing sector. For industrial professionals, understanding the complete lifecycle and performance parameters of these components is crucial for informed procurement and project execution.

Current Industry Trends and Market Outlook

The market for industrial flanges, particularly in the carbon steel segment, is characterized by evolving technological advancements and stringent regulatory requirements. Key trends include a growing emphasis on high-pressure and high-temperature applications, the need for enhanced corrosion resistance, and the continuous drive towards greater operational efficiency and safety. The demand for china carbon steel flange is buoyed by robust industrial growth in sectors like petrochemicals, oil and gas, power generation, and water treatment infrastructure across Asia, Africa, and South America.

Recent market analysis indicates a steady compound annual growth rate (CAGR) for the global flange market, with significant contributions from the Asia-Pacific region. This growth is driven by massive infrastructure projects, expansion of existing industrial facilities, and the replacement of aging pipeline systems. Manufacturers are increasingly focusing on automation and precision engineering to meet the exacting standards of international specifications such as ASME carbon steel flange standards, ensuring products deliver consistent performance and reliability.

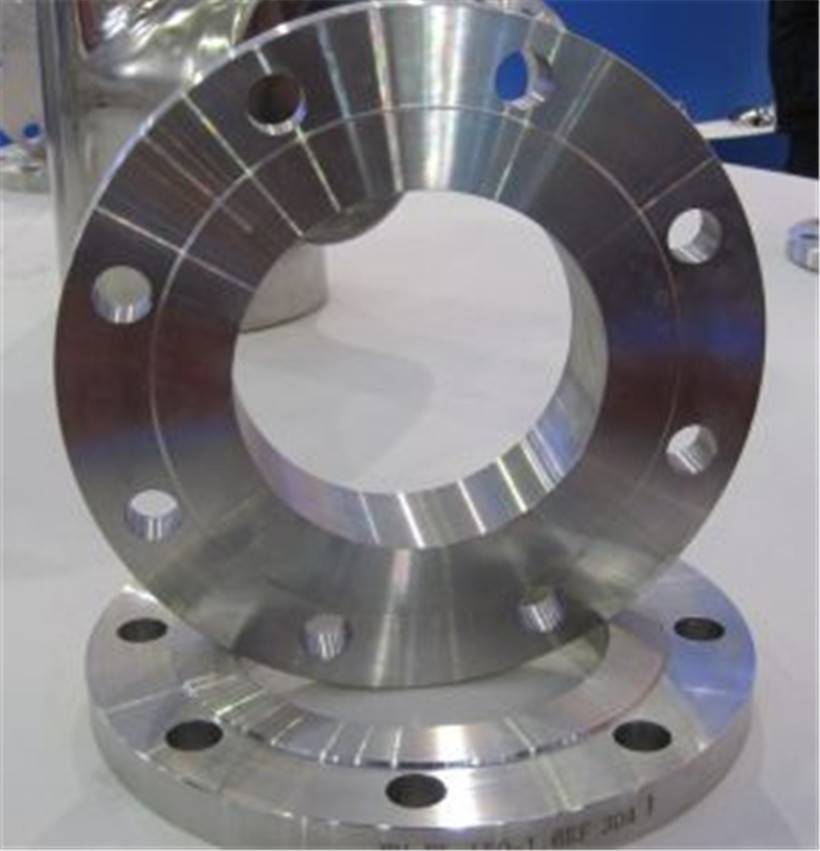

Figure 1: Typical industrial application demonstrating the integration of carbon steel flanges.

Detailed Manufacturing Process Flow for Carbon Steel Flanges

The production of high-quality carbon steel flanges involves a series of meticulously controlled processes to ensure dimensional accuracy, material integrity, and optimal performance. This section outlines the typical manufacturing flow for an ANSI Forged Carbon Steel Flange:

1. Material Selection and Preparation

- Raw Material: High-grade carbon steel billets or bars are selected based on specific chemical composition requirements (e.g., ASTM A105, A350 LF2 for low-temperature service). These materials offer excellent strength and weldability.

- Cutting: The raw material is precisely cut into appropriate sizes, often using sawing or flame cutting, to minimize waste and prepare for the next stage.

2. Forging Process (Preferred for ANSI Forged Carbon Steel Flange)

- Heating: The cut steel is heated in an induction furnace or gas-fired furnace to a specific forging temperature (typically 1100-1250°C).

- Forging: The heated billet is then shaped using powerful hydraulic presses or hammers. This plastic deformation process refines the grain structure, enhances mechanical properties, and eliminates internal voids, resulting in superior strength and impact resistance compared to cast carbon steel flange. Common forging methods include open die forging and closed die forging, depending on the flange type (e.g., weld neck steel flange requires precise neck formation).

3. Heat Treatment

- Normalizing/Annealing: After forging, flanges undergo heat treatment to relieve internal stresses, improve ductility, and homogenize the grain structure. Normalizing (heating to austenitic temperature and cooling in air) is common for carbon steel flanges.

- Quenching & Tempering (for specific applications): For enhanced hardness and strength, some flanges may undergo quenching followed by tempering.

4. CNC Machining

- Rough Machining: Excess material is removed to bring the flange close to its final dimensions.

- Finish Machining: High-precision CNC machines are used to achieve exact dimensions for bore, face, bolt holes, and surface finish, conforming to standards like ASME B16.5 and B16.47. This critical step ensures proper sealing and fitment.

5. Inspection and Testing

- Dimensional Inspection: Verification of all dimensions against ASME/ANSI standards using calipers, micrometers, and gauges.

- Non-Destructive Testing (NDT): Techniques like Magnetic Particle Inspection (MPI) or Ultrasonic Testing (UT) are performed to detect internal or surface defects.

- Mechanical Testing: Tensile strength, yield strength, elongation, and hardness tests are conducted on test coupons from the same heat treatment batch.

- Hydrostatic Testing: Although not always required for flanges alone, material integrity might be verified with similar pressure tests on components they will be integrated into.

- Material Traceability: Full traceability from raw material to finished product is maintained, often certified by ISO 9001.

6. Surface Treatment and Packaging

- Coating: Flanges are typically coated with anti-rust oil, yellow paint, or hot-dip galvanized for corrosion protection during storage and transit.

- Marking: Each flange is clearly marked with size, pressure rating, material grade, and manufacturer’s logo according to industry standards.

- Packaging: Secure packaging ensures safe delivery to the client.

Figure 2: Representation of advanced CNC machining for flange production.

Technical Specifications of ANSI Forged Carbon Steel Flanges

Understanding the precise technical specifications is crucial for selecting the correct china carbon steel flange for any given application. Our ANSI Forged Carbon Steel Flanges are manufactured to meet or exceed international standards, ensuring compatibility and reliability across various industrial systems.

Key Specifications and Standards:

- Material Grades: ASTM A105 (Standard Specification for Carbon Steel Forgings for Piping Applications), ASTM A350 LF2 (Standard Specification for Carbon and Low-Alloy Steel Forgings, Requiring Notch Toughness Testing for Piping Components).

- Manufacturing Standards: ASME B16.5 (Pipe Flanges and Flanged Fittings NPS ½ through NPS 24 Metric/Inch Standard), ASME B16.47 (Large Diameter Steel Flanges NPS 26 Through NPS 60 Metric/Inch Standard), API 6A (Wellhead and Christmas Tree Equipment).

- Pressure Ratings (Class): 150#, 300#, 600#, 900#, 1500#, 2500#. These classes dictate the maximum allowable working pressure and temperature.

- Facing Types: Raised Face (RF), Flat Face (FF), Ring Type Joint (RTJ), Lap Joint Face (LJF), Tongue and Groove (T&G). The facing type is critical for gasket selection and sealing integrity.

- Types of Flanges: Weld Neck, Slip-On, Blind, Socket Weld, Lap Joint, Threaded, Orifice.

Product Specification Table: ASTM A105 Forged Carbon Steel Weld Neck Flange

These specifications ensure that each ASME carbon steel flange delivers optimal performance under its designated operating conditions, providing a service life typically exceeding 20-30 years when properly installed and maintained.

Application Scenarios and Technical Advantages

The versatility and robustness of carbon steel flanges make them indispensable across a wide spectrum of industries. Their advantages extend beyond mere connection points, offering critical functional benefits.

Target Industries:

- Petrochemical and Oil & Gas: Used in pipelines, refineries, and offshore platforms for transporting crude oil, natural gas, and refined products under high pressure and varying temperatures.

- Power Generation: Essential in thermal and nuclear power plants for steam lines, cooling water systems, and fuel lines.

- Water Supply & Drainage: Critical for municipal water treatment plants, pumping stations, and large-scale irrigation systems.

- Metallurgy & Mining: Employed in process piping for conveying slurries, chemicals, and water in harsh environments.

- Chemical Processing: For transporting various chemicals, ensuring leak-free and safe operations.

Demonstrated Advantages:

- Structural Integrity and Strength: Forged carbon steel provides superior mechanical strength, allowing for high-pressure applications with minimal risk of failure. This is particularly vital in situations where extreme forces are present.

- Cost-Effectiveness: Compared to alloy steel or stainless steel flanges, carbon steel offers a more economical solution without significantly compromising performance in suitable environments, contributing to energy saving in budget allocation.

- Weldability: Carbon steel is highly weldable, facilitating easier installation and maintenance, especially for weld neck steel flange types that require butt welding to the pipe.

- Wide Temperature Range: Standard carbon steel flanges perform reliably within a broad temperature range, from sub-zero (with specific grades like A350 LF2) to elevated temperatures, making them versatile for many processes.

- Corrosion Resistance (Enhanced): While not inherently corrosion-resistant like stainless steel, carbon steel flanges can be effectively treated with coatings (e.g., galvanization, epoxy paint) to resist corrosion in specific environments, extending their service life and ensuring long-term operational integrity.

- Sealing Efficiency: Precision-machined flange faces, when combined with appropriate gaskets, provide highly effective and leak-proof connections, crucial for maintaining process efficiency and preventing environmental hazards.

Figure 3: Flanges in a complex refinery piping network, highlighting their critical role.

Vendor Comparison and Customized Solutions

Choosing the right supplier for china carbon steel flange is a critical decision that impacts project timelines, budget, and long-term operational reliability. While many manufacturers exist, distinguishing factors include manufacturing capability, quality control, adherence to international standards, and capacity for customization.

Key Factors for Vendor Comparison:

- Certifications: Verify ISO 9001 for quality management, PED (Pressure Equipment Directive) for European market, and specific product certifications like API.

- Manufacturing Capacity: Assess production volume, lead times, and ability to handle large or specialized orders.

- Quality Control: Inquire about internal QA/QC procedures, traceability, and independent third-party inspection capabilities.

- Technical Support: Availability of engineering support for design, material selection, and troubleshooting.

- Experience & Reputation: Years in service, client testimonials, and project references in relevant industries.

Product Comparison: Forged vs. Cast Carbon Steel Flanges

Customized Solutions:

Recognizing that off-the-shelf solutions may not always meet unique project demands, leading suppliers of china carbon steel flange offer extensive customization capabilities. This includes:

- Special Dimensions: Manufacturing flanges outside standard ASME B16.5 or B16.47 dimensions.

- Unique Material Grades: Sourcing and forging specific carbon steel alloys with enhanced properties for particular corrosive or thermal conditions.

- Proprietary Designs: Producing flanges based on client-provided drawings and specifications, including custom facing types, bore configurations, or bolt hole patterns.

- Special Coatings and Linings: Applying specialized internal or external coatings for advanced corrosion resistance or non-stick properties.

- Small Batch Production: Catering to niche requirements that do not fit mass production schedules.

Figure 4: A selection of specialized carbon steel flanges designed for unique project requirements.

Application Case Studies & Customer Feedback

Real-world application demonstrates the proven reliability and performance of quality carbon steel flanges. Our extensive experience serving diverse industries highlights our commitment to delivering superior products.

Case Study 1: Major Refinery Expansion Project

Client: Leading Middle Eastern Oil & Gas Corporation

Challenge: The client required thousands of high-pressure ASME carbon steel flange (Class 600# and 900# Weld Neck Flanges, A105) for a critical crude oil processing unit expansion. Strict adherence to delivery schedules and material traceability was paramount.

Solution: We supplied 4,500 pieces of ASME B16.5 Weld Neck Flanges over an 8-month period. Each batch underwent rigorous third-party inspection (TPI) by Bureau Veritas and was accompanied by EN 10204 3.1 certification. Our robust manufacturing process and supply chain management ensured all deadlines were met, preventing costly project delays.

Outcome: The project was completed on time, with zero reported flange-related failures or quality discrepancies during commissioning and initial operation. The client praised our meticulous documentation and consistent product quality.

Case Study 2: Municipal Water Treatment Plant Upgrade

Client: Large European Municipal Water Authority

Challenge: Upgrading aging infrastructure required corrosion-resistant flanges for a new wastewater treatment section. Budget constraints were a factor, making standard stainless steel prohibitive for certain non-potable lines.

Solution: We proposed and supplied hot-dip galvanized china carbon steel flange (ASTM A105 Slip-On and Blind Flanges, Class 150#) for non-critical, lower-pressure lines. The galvanization provided excellent corrosion resistance at a significantly lower cost than stainless steel, aligning with the project’s budgetary requirements.

Outcome: The client achieved substantial cost savings while maintaining adequate corrosion protection for the specified service conditions. Our technical team provided detailed specifications on coating thickness and longevity, reassuring the client of the long-term viability of the solution. The project has been operational for 5 years with no issues related to flange integrity.

Customer Feedback:

“The consistent quality and adherence to specifications of their carbon steel flange products have made them a trusted partner for our ongoing projects. Their ability to deliver on time, even for complex orders, is exceptional.”

“For critical applications where safety cannot be compromised, we rely on forged flanges. Their ANSI Forged Carbon Steel Flanges have consistently met our stringent engineering requirements.”

Trustworthiness: FAQ, Lead Time, Warranty & Support

Building lasting relationships with B2B clients relies on transparency, reliability, and robust support. Here’s what you can expect:

Frequently Asked Questions (FAQ):

A: For standard ANSI B16.5 flanges in common sizes and pressure classes, our lead time typically ranges from 3-5 weeks from order confirmation. Custom or large volume orders may require 6-10 weeks, depending on complexity and material availability.

A: Yes, all our flanges are supplied with EN 10204 3.1 MTCs, providing full traceability from raw material to finished product, including chemical analysis and mechanical test results. We also facilitate 3.2 certification by independent third-party inspectors upon request.

A: We offer a standard 12-month warranty from the date of shipment against manufacturing defects and material non-conformities, provided the flanges are installed and used according to industry standards and specifications.

A: We understand that project timelines can be critical. While our standard lead times are optimized, we do offer expedited manufacturing and shipping options for urgent requirements. Please contact our sales team to discuss specific needs and feasibility.

Lead Time & Fulfillment Details:

- Standard Production: As noted above, typical 3-5 weeks for most ASME B16.5 items.

- Custom & Large Volume: 6-10 weeks, depending on material sourcing and complexity.

- Logistics: We offer various Incoterms (EXW, FOB, CIF, DDP) and can arrange shipping via sea, air, or land to meet global delivery requirements. Our logistics partners are experienced in handling industrial components, ensuring safe and timely arrival.

Warranty Commitments:

Our products undergo stringent quality control at every stage. We warrant our ANSI Forged Carbon Steel Flanges to be free from defects in material and workmanship for a period of 12 months from the date of initial shipment. This warranty covers replacement or repair of non-conforming products identified within the warranty period, provided proper storage, installation, and usage practices are followed.

Customer Support & After-Sales Service:

Our commitment extends beyond delivery. We provide comprehensive customer support, including:

- Dedicated Account Managers: A single point of contact for all your inquiries and project needs.

- Technical Assistance: Our engineering team is available to assist with material selection, compatibility questions, and installation guidance.

- Responsive Issue Resolution: A streamlined process for addressing any concerns or claims, ensuring prompt and effective solutions.

Figure 5: Quality inspection of finished carbon steel flanges.

Conclusion

The selection of high-quality china carbon steel flange is foundational to the safety, efficiency, and longevity of industrial piping systems. By understanding the detailed manufacturing processes, adhering to rigorous technical specifications, and leveraging strategic supplier partnerships, B2B decision-makers can ensure optimal project outcomes. Our ANSI Forged Carbon Steel Flanges, backed by comprehensive certifications, advanced manufacturing, and dedicated customer support, offer a reliable and cost-effective solution for demanding industrial applications worldwide.

References

- American Society of Mechanical Engineers (ASME). ASME B16.5: Pipe Flanges and Flanged Fittings NPS ½ Through NPS 24 Metric/Inch Standard. New York: ASME, 2020.

- ASTM International. ASTM A105/A105M: Standard Specification for Carbon Steel Forgings for Piping Applications. West Conshohocken, PA: ASTM International, 2023.

- International Organization for Standardization (ISO). ISO 9001: Quality management systems – Requirements. Geneva: ISO, 2015.

- European Committee for Standardization (CEN). EN 10204: Metallic products – Types of inspection documents. Brussels: CEN, 2004.

Hebei Mingda International Trading Company is a trading company which is specialized in castings, ODM Ductile Iron Manhole Cover forgings and machinery parts.Our products include all kinds of raw castings to be made of ductile iron , grey iron , brass , stainless steel and aluminums, machined castings and forged parts .ODM Ductile Iron Covers To make these parts according to the customers’Custom Iron Casting drawings , we have relative suitable production craft and equipments, such as resin sand , sand mould , hot core boxes , lost-wax , lost –foam and so on Iron Casting Manufacturer Custom.Specially for hydrant bodies and valves’Ductile Iron Manhole Cover Manufacturer bodies, we have collected rich experience for these products in the past 16 year’s actual production, Now we are proud of our products with good surface and high quality material. Iron Casting ManufacturerWhatever,we have been trying our best to provide our customers with better quality castings by improving production crafts and more careful quality control.Cast Iron Castings Manufacturer|super blog