Industry Trends in Aluminum Parts Manufacturing

The global demand for high-performance, lightweight components continues to drive innovation in aluminum parts manufacturing. Particularly, the market for china aluminum parts machining is experiencing robust growth, fueled by advancements in CNC technology, material science, and automation. Key trends include the increasing adoption of Industry 4.0 principles, enhanced focus on sustainable manufacturing practices, and the development of specialized aluminum alloys with superior strength-to-weight ratios and corrosion resistance.

Moreover, the rise of electric vehicles (EVs) and aerospace innovations has significantly augmented the need for precision-machined aluminum components, which are critical for reducing vehicle weight and improving fuel efficiency or battery range. China, with its sophisticated manufacturing infrastructure and competitive supply chain, has emerged as a crucial hub for high-quality aluminum parts production, serving diverse global industries. The emphasis is increasingly on rapid prototyping, shorter lead times, and the capability to handle complex geometries with tight tolerances.

Detailed Process Flow: From Raw Material to Finished Component

The manufacturing process for high-quality aluminum parts involves a series of meticulously controlled steps, ensuring precision, integrity, and performance. For companies specializing in china aluminum parts machining, the integration of various techniques, from initial material preparation to final inspection, is paramount.

1. Material Selection and Preparation

The journey begins with selecting the appropriate aluminum alloy, such as A380, A356, ADC12, or 6061, based on the application’s specific requirements for strength, ductility, corrosion resistance, and thermal conductivity. These alloys are sourced from reputable suppliers to ensure material purity and consistent mechanical properties. Materials undergo initial quality checks for composition and structural integrity.

2. Primary Forming Process (Casting/Forging)

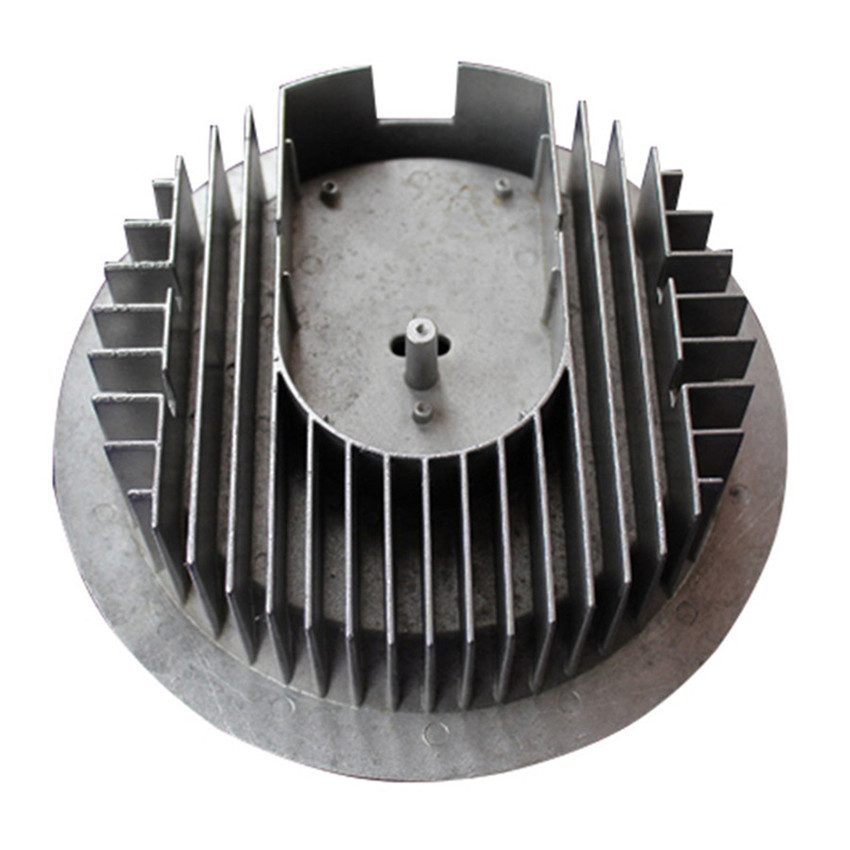

- Die Casting: For OEM custom die casting aluminum parts, molten aluminum is injected under high pressure into steel molds. This method is ideal for producing complex shapes with high precision and excellent surface finish at a high production rate. It’s particularly common for mass-produced components.

- Sand Casting: Used for larger parts or lower volumes, where sand molds are created. Offers flexibility in design but typically requires more post-machining.

- Forging: Aluminum billets are heated and shaped under compressive forces. This process enhances grain structure, leading to superior strength and fatigue resistance, often preferred for critical structural components.

3. CNC Machining

After primary forming, the raw aluminum components undergo Computer Numerical Control (CNC) machining. This highly precise subtractive manufacturing process uses automated tools to remove material, achieving the final dimensions, intricate features, and specified surface finishes. Multi-axis CNC machines (3-axis, 4-axis, 5-axis) are employed to handle complex geometries with tolerances often down to ±0.01mm. This stage is crucial for perfecting the china aluminum parts machining product.

4. Heat Treatment (if required)

Depending on the alloy and desired mechanical properties, parts may undergo heat treatment processes such as solution heat treatment and artificial aging (e.g., T6 temper for 6061 alloy). This optimizes the aluminum’s strength, hardness, and ductility.

5. Surface Finishing

Various surface treatments can be applied to enhance corrosion resistance, wear resistance, aesthetics, or electrical conductivity. Common finishes include anodizing (clear, colored, hard-coat), powder coating, sandblasting, polishing, and passivation.

6. Quality Control and Testing

Rigorous testing is integrated throughout the process. Final inspection includes:

- Dimensional Inspection: Using CMM (Coordinate Measuring Machine), calipers, micrometers, and gauges to verify all dimensions against CAD models.

- Material Composition: Spectrometer analysis to confirm alloy composition.

- Mechanical Properties: Tensile strength, yield strength, hardness (Rockwell, Brinell) testing.

- Non-Destructive Testing (NDT): X-ray, ultrasonic, or dye penetrant inspection for internal defects.

- Surface Finish Inspection: Roughness testers and visual checks.

Testing standards typically adhere to ISO 9001, ANSI, ASTM, and client-specific specifications, ensuring compliance and product longevity. The service life of such precisely manufactured parts is significantly extended, often exceeding 15-20 years in less demanding applications, and many years in critical environments due to superior material and process control.

Technical Specifications and Material Characteristics

Understanding the technical specifications of aluminum alloys is critical for engineers and procurement specialists. The properties directly influence the part’s performance in various applications. Here’s a look at common aluminum alloys used in china aluminum parts machining and their typical parameters:

These specifications are crucial for ensuring components meet structural and environmental demands. The precision in china aluminum parts machining directly translates into optimal performance in the field.

Application Scenarios and Technical Advantages

Precision china aluminum parts machining finds extensive application across a multitude of industries, driven by aluminum’s inherent advantages: high strength-to-weight ratio, excellent thermal and electrical conductivity, corrosion resistance, and recyclability. These attributes make it an ideal material for components in demanding environments.

Target Industries and Advantages:

- Automotive and Electric Vehicles: Components like engine blocks, transmission housings, chassis parts, battery enclosures, and structural frames. Advantages: Significant weight reduction leading to improved fuel efficiency or extended EV range, enhanced heat dissipation, and superior crash performance.

- Aerospace and Defense: Aircraft fuselage components, wing ribs, engine parts, hydraulic manifold blocks, and satellite structures. Advantages: Unmatched strength-to-weight ratio crucial for payload capacity and fuel economy, exceptional fatigue resistance, and ability to withstand extreme temperatures.

- Electronics and Telecommunications: Heat sinks, EMI/RFI shielding, connector housings, and electronic enclosures. Advantages: Excellent thermal management properties (heat dissipation), effective electromagnetic shielding, and lightweight for portable devices.

- Petrochemical and Chemical Processing: Valve bodies, pump housings, fittings, and instrumentation enclosures. Advantages: Superior corrosion resistance against various chemicals, non-sparking properties, and durability in harsh environments.

- Medical Devices: Instrument housings, surgical tool components, and diagnostic equipment parts. Advantages: Biocompatibility, ease of sterilization, lightweight for portability, and precise machining for intricate designs.

- Industrial Machinery and Robotics: Robot arms, gearboxes, actuator housings, and precision machine bases. Advantages: High rigidity and stability for precision movement, corrosion resistance for long service life, and lightweight for reduced inertia.

The ability to custom machine parts, including complex geometries and tight tolerances, makes aluminum components indispensable for critical applications demanding both performance and longevity. The advantages of energy saving through lightweight design and corrosion resistance for extended operational life are paramount.

Vendor Comparison: Choosing the Right China Aluminum Parts Wholesaler

When sourcing china casting aluminum parts wholesaler or china aluminum parts machining wholesaler, selecting the right partner is crucial for project success. A robust vendor comparison considers several factors beyond just price, including technical capability, quality assurance, communication, and logistical expertise.

A reputable china aluminum parts machining wholesaler will invest in advanced machinery, skilled personnel, and stringent quality protocols to ensure product consistency and customer satisfaction. The long-term benefits of a reliable supply chain far outweigh initial cost savings from less capable vendors.

Customized Solutions and Expertise

Many industries require highly specialized aluminum components that cannot be met by off-the-shelf solutions. This is where the expertise of a custom china aluminum parts machining provider becomes invaluable. Offering tailored solutions involves comprehensive support from design to delivery.

Design for Manufacturability (DFM)

Experienced manufacturers provide DFM services, collaborating with clients to optimize designs for efficient and cost-effective production while maintaining functional integrity. This includes material selection, tolerance analysis, and suggesting design modifications to improve castability or machinability, ultimately reducing costs and accelerating time-to-market.

Prototyping and Tooling Development

Rapid prototyping through advanced CNC machining or 3D printing allows for quick validation of designs before committing to expensive production tooling. For die casting, in-house tooling capabilities ensure faster mold development and modification cycles, critical for complex OEM custom die casting aluminum parts.

Value-Added Services

Custom solutions often extend beyond just machining. Providers may offer assembly, specialized testing, kitting, or custom packaging services. These integrated solutions simplify the supply chain for clients, reducing their internal handling and logistics costs.

Application Case Studies

Case Study 1: Automotive EV Battery Housing

A leading EV manufacturer required a lightweight, robust, and thermally efficient housing for their new generation battery packs. A specialized china aluminum parts machining provider proposed a die-cast A356 aluminum alloy solution, followed by precision CNC machining for sealing surfaces and mounting points. The design optimized for thermal dissipation, crucial for battery longevity and performance. The project delivered a 15% weight reduction compared to previous designs and improved thermal efficiency by 10%, directly contributing to extended vehicle range.

Case Study 2: Aerospace Actuator Bracket

For a critical aerospace application, a client needed high-strength, fatigue-resistant actuator brackets. Utilizing 6061-T6 aluminum, the manufacturer employed a combination of forging for superior grain structure and 5-axis CNC machining to achieve complex contours and tight dimensional tolerances (±0.02mm). Post-machining, hard-coat anodizing was applied for enhanced wear and corrosion resistance. The parts successfully passed stringent aerospace certification tests, including stress and vibration analysis, demonstrating exceptional reliability and a projected service life exceeding 20 years.

Trustworthiness and Support

Frequently Asked Questions (FAQ)

- Q: What aluminum alloys can be machined?

A: We commonly work with A380, A356, ADC12, 6061, 7075, and many other aluminum alloys, depending on the client’s specific requirements. Our engineering team can assist in material selection. - Q: What are your typical lead times for custom aluminum parts?

A: Lead times vary based on complexity, order volume, and specific processes. For prototyping, it can be as short as 2-4 weeks. For mass production, initial tooling might take 4-6 weeks, with subsequent production runs typically 3-5 weeks. We provide detailed timelines with each quotation. - Q: What quality control measures do you have in place?

A: We adhere to ISO 9001:2015 certified processes, employ CMM, spectral analysis, tensile testing, and conduct rigorous in-process and final inspections. Full material and dimensional reports are provided. - Q: Can you handle complex geometries and tight tolerances?

A: Yes, our advanced 5-axis CNC machining capabilities and experienced machinists enable us to produce parts with highly complex geometries and tolerances as tight as ±0.01mm.

Lead Time & Fulfillment

Our commitment to efficient fulfillment is supported by streamlined production schedules and robust supply chain management. Typically, tooling for new OEM custom die casting aluminum parts projects can be completed within 4-6 weeks, with initial samples following shortly after. Production runs are then executed within 3-5 weeks, depending on volume. We offer flexible shipping options, including air and sea freight, to meet global client demands and delivery schedules.

Warranty Commitments

We stand behind the quality of our china aluminum parts machining products. All manufactured parts come with a material and workmanship warranty against defects. Specific warranty terms will be outlined in our contractual agreements, typically covering components for a period of 12-24 months post-delivery, ensuring peace of mind for our B2B partners.

Customer Support Information

Our dedicated customer support team is available to assist with inquiries, technical support, and order tracking. We provide responsive communication channels, including email, phone, and online portals, ensuring that clients receive timely assistance and updates throughout their project lifecycle. Post-sales support is a cornerstone of our service, aiming for long-term partnerships built on trust and reliability.

References

- ASM International. (2018). ASM Handbook, Volume 2: Properties and Selection: Nonferrous Alloys and Special-Purpose Materials.

- American Society for Testing and Materials (ASTM International). (Current Standards). Various standards for aluminum alloys and testing methods.

- International Organization for Standardization (ISO). (Current Standards). ISO 9001:2015 Quality Management Systems – Requirements.

- Society of Automotive Engineers (SAE International). (Current Standards). Specific standards for materials and processes in automotive and aerospace.

- Mordor Intelligence. (2023). Aluminum Market – Growth, Trends, COVID-19 Impact, and Forecasts (2023 – 2028).

Hebei Mingda International Trading Company is a trading company which is specialized in castings, ODM Ductile Iron Manhole Cover forgings and machinery parts.Our products include all kinds of raw castings to be made of ductile iron , grey iron , brass , stainless steel and aluminums, machined castings and forged parts .ODM Ductile Iron Covers To make these parts according to the customers’Custom Iron Casting drawings , we have relative suitable production craft and equipments, such as resin sand , sand mould , hot core boxes , lost-wax , lost –foam and so on Iron Casting Manufacturer Custom.Specially for hydrant bodies and valves’Ductile Iron Manhole Cover Manufacturer bodies, we have collected rich experience for these products in the past 16 year’s actual production, Now we are proud of our products with good surface and high quality material. Iron Casting ManufacturerWhatever,we have been trying our best to provide our customers with better quality castings by improving production crafts and more careful quality control.Cast Iron Castings Manufacturer|super blog