What Ireland’s Sites Are Choosing for Stormwater: The Quiet Rise of Channel Drain Ireland

Drive past any new logistics yard outside Dublin or a seaside build in Galway and, if you peek along the kerb line, you’ll spot it: the slim, gritted edge of a polymer concrete trench. To be honest, Channel Drain Ireland has moved from “nice-to-have” to baseline—thanks to intense cloudbursts, tighter SUDS expectations, and the simple fact that no one wants a flooded forecourt at 4pm on a Friday.

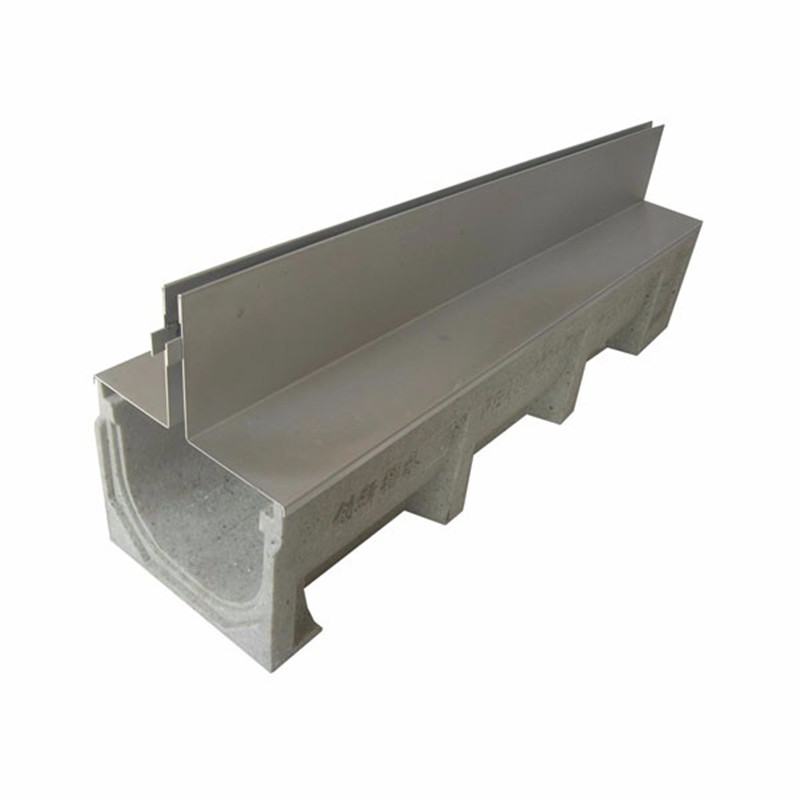

The Product at a Glance

I’ve been tracking heavy-duty trench systems for years. The Heavy Duty Polymer Concrete Channel Drain from MingDa Metals—made in Gelan Building, No.256 Xisanzhuang Street, Shijiazhuang, Hebei, China—shows up frequently in Irish tender packs now. The web page calls out “plastic” in a short description (a common catalog quirk), but the field units here are polymer concrete bodies with ductile iron or composite grates, locked down for HGV traffic. In fact, Channel Drain Ireland demand has tilted strongly toward EN 1433 D400–F900 load classes for mixed-use car parks and distribution aprons.

Core specifications (typical Ireland supply)

| Parameter | Value (≈, real‑world use may vary) |

|---|---|

| Body material | Polymer concrete (low porosity, high compressive strength) |

| Grate options | Ductile iron EN-GJS-500, galvanised steel, or composite |

| Load classes (EN 1433) | C250, D400, E600, F900 (site-specific) |

| Channel widths | 100 / 150 / 200 / 300 mm internal; slot 8–18 mm |

| Hydraulic capacity | ≈ 5–80 L/s per 1 m (depends on slope/width) |

| Temperature range | −40 °C to +80 °C intermittent |

| Chemical/salt resistance | Good; ISO 9227 salt-spray tested |

| Packaging & productivity | Standard export package; ≈100 ton/month output |

How it’s made, tested, and expected to last

Manufacture is typically vibration-cast or compression-moulded polymer concrete with quartz aggregate and resin binders; grates are cast in ductile iron and hot-dip galvanised where specified. Joints use tongue-and-groove with elastomeric sealant for watertight runs. Testing aligns with EN 1433 (load, deflection, security of locking) and ISO 9227 for corrosion on metallics. Service life? Many customers say 25–40 years is realistic on Irish sites, and I’ve seen older polymer channels still behaving after decades—maintenance is the clincher.

Where it’s used—and why

- Retail car parks and forecourts (D400), quick install, low maintenance.

- Logistics yards and ports (E600–F900), high axle loads, anti-rattle locking.

- Residential driveways and patios (C250), discreet slot finishes.

- Distilleries and food plants, chemical resistance and easy washdown.

- Data centres, predictable hydraulics for stormwater management.

Compliance-wise, Channel Drain Ireland projects align to EN 1433, CE/DoP under the EU CPR, TII Specification for Road Works, and, for urban builds, SUDS guidance like CIRIA C753 and the GDSDS in Greater Dublin.

Field notes (mini case studies)

Galway coastal home: 100 mm slot drain along a south-facing patio cut surface water sheeting; homeowner told me maintenance dropped to “a quick brush after storms.”

Dublin logistics hub: 300 mm channels, E600 grates; after 12 months, site manager reported ≈40% fewer ponding incidents versus the old gully layout.

Cork distillery yard: polymer concrete with sealed joints; lab swabs and visual checks showed no resin softening after routine ethanol washdown.

Vendor snapshot: cost, lead-time, confidence

| Vendor | Typical status for Ireland | Notes |

|---|---|---|

| MingDa Metals (origin China) | EN 1433 compliant; CE/DoP supplied; lead time ≈4–7 weeks to Dublin | Strong value; custom widths/grates; export packaging solid |

| Irish distributor A | Stock on D400 skus; 24–72 hr delivery | Higher unit cost; great site support |

| EU brand B | Premium F900 options; 1–3 week lead times | Top finish; limited customization windows |

Installation and maintenance—quick run-through

Methods are familiar: set channels on concrete bed (C20/25), check line/fall, connect outlets, lock grates, and pour surround to spec. Testing on completion should verify line, seal integrity, and grate locking torque. Annual maintenance? Vacuum or lift-and-scrape; many sites schedule pre-winter checks. That’s why Channel Drain Ireland keeps winning: predictable installs, predictable upkeep.

Sources and standards

- EN 1433: Drainage channels for vehicular and pedestrian areas.

- Construction Products Regulation (EU) No 305/2011; CE and DoP requirements.

- ISO 9227: Corrosion tests in artificial atmospheres — Salt spray tests.

- CIRIA C753: The SuDS Manual (UK/Ireland practice).

- TII Specification for Road Works (Transport Infrastructure Ireland).

- Greater Dublin Strategic Drainage Study (GDSDS) guidance documents.

Hebei Mingda International Trading Company is a trading company which is specialized in castings, ODM Ductile Iron Manhole Cover forgings and machinery parts.Our products include all kinds of raw castings to be made of ductile iron , grey iron , brass , stainless steel and aluminums, machined castings and forged parts .ODM Ductile Iron Covers To make these parts according to the customers’Custom Iron Casting drawings , we have relative suitable production craft and equipments, such as resin sand , sand mould , hot core boxes , lost-wax , lost –foam and so on Iron Casting Manufacturer Custom.Specially for hydrant bodies and valves’Ductile Iron Manhole Cover Manufacturer bodies, we have collected rich experience for these products in the past 16 year’s actual production, Now we are proud of our products with good surface and high quality material. Iron Casting ManufacturerWhatever,we have been trying our best to provide our customers with better quality castings by improving production crafts and more careful quality control.Cast Iron Castings Manufacturer|super blog