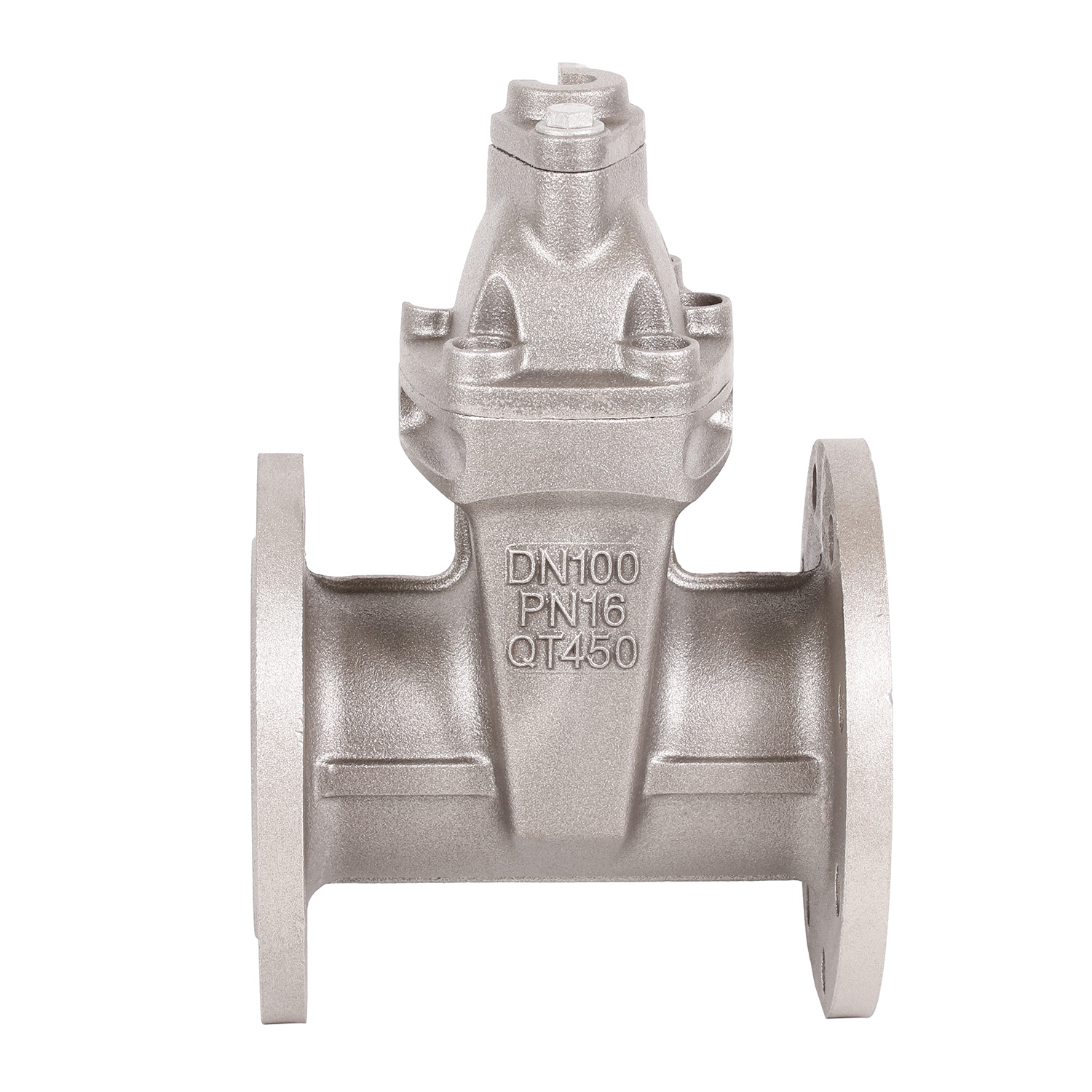

- Gate Valve

- Features: Full open/full close, low fluid resistance, suitable for medium cutoff.

- Structure: Rising stem (e.g., Z45X-16Q), non-rising stem.

- Applications: Water supply, drainage, sewage treatment.

- Globe Valve

- Features: Flow regulation, good sealing, but higher flow resistance.

- Structure: Straight-through, angle-type (e.g., J41H-16C).

- Applications: Chemical, petroleum pipelines.

- Butterfly Valve

- Features: Compact size, flexible operation, suitable for large-diameter pipelines.

- Structure: Centerline type, double eccentric (e.g., D71X-16Q).

- Applications: Fire protection systems, HVAC.

- Check Valve

- Features: Automatically prevents backflow.

- Types: Swing type, lift type (e.g., H44X-10Q).

- Applications: Pump outlets, water supply systems.

- Ball Valve

- Features: 90° rotation for rapid on/off control.

- Material: Floating ball, fixed ball (e.g., Q41F-16C).

- Applications: Chemical, food processing industries.

- Gray Cast Iron (HT200/HT250)

- Characteristics: Low cost, wear-resistant, but brittle.

- Applications: Low-pressure, ambient-temperature environments (e.g., water supply).

- Ductile Iron (QT450-10)

- Characteristics: High strength, good toughness, can replace steel valves.

- Applications: Medium-high pressure, high-temperature environments (e.g., chemical, fire protection).

- Pressure Ratings

- ISO: PN6/PN10/PN16/PN25 (equivalent to Class 150/300, etc.).

- ANSI: Class 150/300/600.

- Nominal Diameter (DN)

- DN50–DN600 (large diameters common in municipal projects).

- Temperature Range

- Gray cast iron: -10°C to 120°C; Ductile iron: -30°C to 200°C.

- Connection Types

- Flange (most common), threaded, wafer, welded.

- Water Supply & Drainage

- Gate valves, butterfly valves for water plants and pump stations.

- HVAC Systems

- Butterfly valves, check valves for chilled water loops.

- Chemical/Petroleum

- Globe valves, ball valves for corrosive media transport.

- Fire Protection

- Butterfly valves, signal butterfly valves for pipeline control.

- Medium Properties

- Corrosive media: Ductile iron with epoxy coating; particulate media: wear-resistant gate valves.

- Pressure & Temperature

- High-pressure/high-temperature environments: Prefer ductile iron to avoid brittleness of gray cast iron.

- Installation Space

- Large-diameter pipelines: Butterfly valves; space-constrained areas: Globe valves.

- Environmental Factors

Hebei Mingda International Trading Company is a trading company which is specialized in castings, ODM Ductile Iron Manhole Cover forgings and machinery parts.Our products include all kinds of raw castings to be made of ductile iron , grey iron , brass , stainless steel and aluminums, machined castings and forged parts .ODM Ductile Iron Covers To make these parts according to the customers’Custom Iron Casting drawings , we have relative suitable production craft and equipments, such as resin sand , sand mould , hot core boxes , lost-wax , lost –foam and so on Iron Casting Manufacturer Custom.Specially for hydrant bodies and valves’Ductile Iron Manhole Cover Manufacturer bodies, we have collected rich experience for these products in the past 16 year’s actual production, Now we are proud of our products with good surface and high quality material. Iron Casting ManufacturerWhatever,we have been trying our best to provide our customers with better quality castings by improving production crafts and more careful quality control.Cast Iron Castings Manufacturer