Inside the shift from iron to composites: a field note from a busy cast grating factory floor

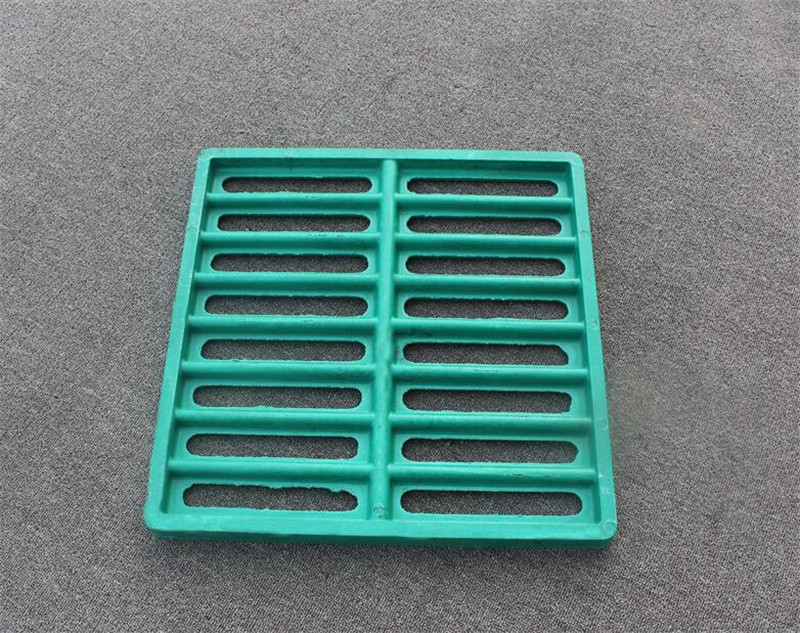

If you’ve ever ordered drainage covers or trench walkways for a municipal job, you’ve probably dealt with a cast iron gratings manufacturer. Lately, though, the calls I get aren’t just about iron. They’re about EN124-compliant fiber composite gratings — lighter, corrosion-proof, and, frankly, a lot kinder during night installs. Mingda’s En124 Fiber Composite Gratings are a good example of where the market is going.

What’s driving the trend

Municipal engineers want EN 124 load ratings with fewer corrosion headaches. Chemical plants don’t want rust, ever. Maintenance crews prefer components they can lift without a crane. To be honest, it’s not about abandoning cast iron entirely — it’s about choosing the right material for the environment. Many customers say composites have cut their install time in half; it seems that’s not just hype when you look at the handling weight.

Product snapshot: En124 Fiber Composite Gratings

Origin: Gelan Building, No.256 Xisanzhuang Street, Shijiazhuang, Hebei, China. Certifications include SGS, CE, ISO 9001:2008. Standard export packaging; ships via ocean, land, or air from Tianjin. Productivity around 100 ton/month.

| Spec | Details (≈ real-world may vary) |

|---|---|

| Load Classes (EN 124) | B125, C250, D400 (project-dependent) |

| Materials | E-glass fiber + unsaturated polyester or vinyl-ester resin; anti-UV grit surface |

| Panel Sizes | 300×300 to 1000×1000 mm; custom on request |

| Thickness | 25–50 mm typical |

| Surface | Anti-slip grit; optional logo/ID embossing |

| Service Life | ≈25–50 years in neutral environments |

Process flow and quality checks

Materials are batched (resin, glass roving, fillers), then laid up in a heated mold for molded FRP grating. After cure, panels are demolded, trimmed, and grit-coated. Testing follows EN 124 static load protocols; flexural per ISO 178 / ASTM D790, water absorption per ASTM D570, and salt-spray per ASTM B117 for coating endurance. Typical flexural strength hits ≈ 200–350 MPa; slip resistance reaches R12–R13 in lab ramps, although site dust can change that.

Where they’re used

- Municipal drainage and sidewalk inlets (C250)

- Roadside trenches and depot yards (D400)

- Chemical plant walkways; wastewater plants (corrosion zones)

- Coastal infrastructure; ports where salt fog is relentless

One buyer told me, “Two people carried what used to need a picker,” which, surprisingly, changed their weekend maintenance plan. That’s the practical upside a cast iron gratings manufacturer offering composites can deliver.

Vendor comparison (field-notes version)

| Vendor | Material | Load Range | Corrosion | Weight | Certs | Lead Time |

|---|---|---|---|---|---|---|

| Traditional Foundry A | Gray/ductile iron | B125–F900 | Needs coating; rust risk | Heavy | EN 124 | 4–8 weeks |

| FRP Specialist B | FRP composite | A15–D400 | Excellent | Light | ISO 9001 | 3–6 weeks |

| Mingda (this cast iron gratings manufacturer) | FRP composite + EN124 focus | B125–D400 | Excellent; salt-spray tested | Light-to-medium | SGS, CE, ISO 9001 | ≈3–5 weeks |

Customization & real projects

Options: color coding, logo embossing, anti-theft locking, spark-safe resin, UV-stabilized topcoat, and non-standard panels. In Shijiazhuang, a storm-drain retrofit swapped corroded iron for D400 composites and cut replacement cycles. At Tianjin port, walkways stayed grippy after 1,000-hour salt spray, per lab checks. Feedback is blunt: “less rust, fewer backaches.”

Final take

Iron isn’t going away, but a versatile cast iron gratings manufacturer that also engineers EN124 composites gives specifiers options. That’s the quiet revolution under our feet.

Authoritative references

- BS EN 124-1:2015 Gully tops and manhole tops for vehicular and pedestrian areas — https://shop.bsigroup.com/products/bs-en-124-1-2015

- ISO 9001 Quality management systems — https://www.iso.org/standard/62085.html

- ASTM B117 Salt Spray (Fog) Testing — https://www.astm.org/b0117-23.html

- ASTM D790 Flexural Properties of Reinforced Plastics — https://www.astm.org/d0790-23.html

- ISO 178 Plastics — Determination of flexural properties — https://www.iso.org/standard/63693.html

Hebei Mingda International Trading Company is a trading company which is specialized in castings, ODM Ductile Iron Manhole Cover forgings and machinery parts.Our products include all kinds of raw castings to be made of ductile iron , grey iron , brass , stainless steel and aluminums, machined castings and forged parts .ODM Ductile Iron Covers To make these parts according to the customers’Custom Iron Casting drawings , we have relative suitable production craft and equipments, such as resin sand , sand mould , hot core boxes , lost-wax , lost –foam and so on Iron Casting Manufacturer Custom.Specially for hydrant bodies and valves’Ductile Iron Manhole Cover Manufacturer bodies, we have collected rich experience for these products in the past 16 year’s actual production, Now we are proud of our products with good surface and high quality material. Iron Casting ManufacturerWhatever,we have been trying our best to provide our customers with better quality castings by improving production crafts and more careful quality control.Cast Iron Castings Manufacturer|super blog