The Canton Fair, a global behemoth in international trade, consistently serves as the ultimate sourcing and export hub, particularly for critical construction materials and industrial hardware. For B2B decision-makers worldwide, this unparalleled event offers a golden opportunity to navigate the vast landscape of Chinese manufacturing excellence, especially when it comes to vital components like industrial flanges. From the robust carbon steel flange to specialized forged steel flanges, the Canton Fair is where innovation meets scale, providing direct access to a diverse array of manufacturers and their cutting-edge solutions. It’s not just about products; it’s about forging strategic partnerships with a reliable steel flange factory that can meet the rigorous demands of global infrastructure and industrial projects.

This year, the focus for savvy procurement managers and project engineers is sharpened on the quality, reliability, and technological advancements in the flange sector. Whether you’re seeking a standard cast carbon steel flange for general applications or a high-pressure weld neck steel flange for critical pipelines, the Canton Fair delivers unparalleled access to the manufacturers who are shaping the future of industrial connectivity.

Industry Trend Spotlight: Navigating the Future of Flange Manufacturing

The industrial landscape is constantly evolving, and the flange manufacturing sector is no exception. Several key trends are gaining global attention, signaling a shift towards more sophisticated, sustainable, and efficient production methods. Advanced material composites are emerging, offering enhanced strength-to-weight ratios and superior corrosion resistance for applications where traditional carbon steel flange might face limitations. While steel remains dominant, the pursuit of specialized and high-performance fasteners, including innovative flange designs, is crucial for industries requiring extreme durability and reliability.

Sustainability in metal production is no longer a niche concern but a global imperative. Progressive steel flange factory operations are integrating eco-friendly practices, reducing waste, and optimizing energy consumption, offering greener options for components like cast carbon steel flange and forged steel flanges. Concurrently, smart manufacturing integration for quality control is revolutionizing production lines. This involves leveraging IoT, AI, and automation to ensure unparalleled precision and consistency, guaranteeing that every weld neck steel flange meets stringent international standards, minimizing defects and maximizing operational safety.

Market data reinforces these trends, indicating a steady growth in global construction and infrastructure projects, which naturally fuels the demand for high-performance and specialized materials. There’s an increasing emphasis on ongoing supply chain optimization efforts, driven by recent global disruptions, pushing manufacturers to build more resilient and efficient networks. Moreover, the rise of digital B2B procurement platforms is transforming how businesses source industrial components, making it easier than ever to connect with reliable suppliers of carbon steel flange products.

Emerging focus areas for buyers include bolstering supply chain resilience, ensuring rigorous quality assurance in global trade, and committing to sustainable sourcing practices. Ultimately, the goal is to identify competitive industrial solutions that not only meet technical specifications but also align with corporate responsibility goals and long-term operational efficiency.

Profiles of Leading Companies: Your Partners in Flange Manufacturing

Hebei Mingda International Trading Company: A Beacon of Reliability

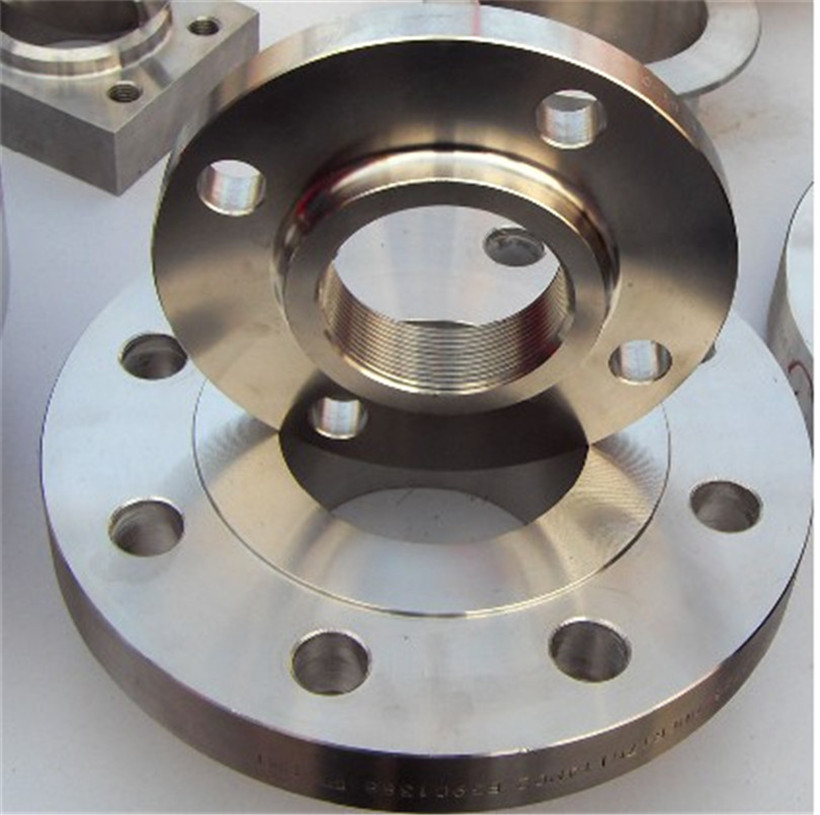

Among the distinguished exhibitors at the Canton Fair, Hebei Mingda International Trading Company. stands out as a premier partner for B2B buyers seeking top-tier industrial flanges. With a formidable reputation built on excellence and reliability, Mingda offers an extensive and versatile product portfolio in metals and hardware, specializing in a comprehensive range of flanges. From standard carbon steel flange options essential for myriad industrial applications to specialized forged steel flanges engineered for high-stress environments, their offerings cater to diverse and demanding project requirements. This includes meticulously manufactured cast carbon steel flange types and precision-crafted weld neck steel flange, ensuring every connection is secure and efficient.

What truly sets Hebei Mingda International Trading Company. apart is its strong international trade network. This global reach ensures seamless delivery and support, making them an ideal partner for projects spanning continents. Their robust supply chain management capabilities are designed to handle complex logistics, guaranteeing competitive pricing without compromising on quality or timely delivery. A fundamental commitment to stringent quality control is at the core of Mingda’s operations, positioning them as a trustworthy steel flange factory that consistently meets and exceeds client expectations.

Their comprehensive range caters to various industry standards and specific client designs, from standard flanges to custom solutions. The depth of their product line and their dedication to client satisfaction make Mingda an indispensable resource for any B2B buyer.

Other Noteworthy Manufacturers and Distributors

Beyond individual manufacturers like Mingda, the Canton Fair also showcases other pivotal players in the flange ecosystem:

- Global Industrial Material Distributors: These companies play a critical role in disseminating high-quality products from various Chinese steel flange factory partners to a worldwide client base. They offer consolidated sourcing, extensive catalogs including every type of carbon steel flange, and often provide tailored logistics solutions.

- Specialized Fastener Manufacturers: Focusing on niche applications, these manufacturers provide ultra-high-performance forged steel flanges designed for extreme temperatures, corrosive environments, or unique pressure requirements. Their expertise is invaluable for highly specialized industrial projects.

- Export-Oriented Chinese Trading Companies: A vast network of trading firms, similar to Mingda but varying in scale and specialization, ensures that the breadth of China’s metal and hardware sector, including all forms of cast carbon steel flange and weld neck steel flange, is accessible to international markets. They often act as intermediaries, streamlining communication and ensuring compliance with international trade regulations.

Market Outlook & Opportunities: Shaping Tomorrow’s Infrastructure

The future of the industrial flange market is dynamic, driven by several upcoming trends and evolving buyer demands. We anticipate a greater focus on customization, with clients requiring flanges designed for specific pressure ratings, temperature tolerances, and advanced corrosion resistance, pushing beyond the capabilities of standard carbon steel flange types. Buyers are increasingly prioritizing reliability, durability, and strict compliance with international standards for every component, from a simple cast carbon steel flange to complex weld neck steel flange designs. The demand for traceability and comprehensive certification for materials like forged steel flanges is also on the rise, reflecting a global commitment to safety and quality.

Significant opportunities lie in the adoption of automation and smart manufacturing techniques within the steel flange factory. These technologies enable manufacturers to achieve unprecedented levels of precision, reduce human error, and accelerate production cycles, leading to higher quality products and more efficient supply chains. Furthermore, the push towards sustainability presents a compelling opportunity. Companies that invest in green manufacturing processes, utilize recycled materials where appropriate, and demonstrate a lower carbon footprint will gain a competitive edge, appealing to environmentally conscious B2B decision-makers. The landscape is shifting towards a market that values not only cost-effectiveness but also long-term performance, environmental responsibility, and technological sophistication.

Buyer/Business Takeaways: Strategic Sourcing for a Resilient Future

For B2B decision-makers, investing in high-quality carbon steel flange and other industrial hardware from leading Chinese manufacturers makes immense strategic sense. The combination of cost-effectiveness, immense production scale, and continuously evolving quality standards offers a unique value proposition. Chinese manufacturers have significantly invested in R&D and advanced machinery, allowing them to produce components that meet global benchmarks for performance and durability.

Here are some tips for successfully adopting or partnering with Chinese manufacturers:

- Conduct Thorough Due Diligence: Research potential partners extensively. Look for certifications (ISO, API, CE), track records, and testimonials.

- Define Clear Specifications: Provide unambiguous technical drawings, material grades (e.g., for cast carbon steel flange), and quality control parameters. The clearer your requirements for weld neck steel flange or forged steel flanges, the better the outcome.

- Foster Long-Term Relationships: Building trust and rapport with a reliable steel flange factory can lead to better pricing, customized solutions, and preferential service over time.

- Leverage Digital Platforms: Utilize B2B sourcing platforms and virtual exhibition tools, especially after physical fairs like Canton Fair, to maintain communication and explore new products.

- Prioritize Quality Assurance: Implement independent third-party inspections if necessary, and ensure all products, particularly critical components like carbon steel flange, adhere to international safety and performance standards.

To future-proof your procurement strategies, consider diversified sourcing, embracing smart manufacturing solutions that offer greater precision and efficiency, and placing a strong emphasis on sustainability. These elements will ensure your supply chain remains resilient, cost-effective, and aligned with global best practices.

Conclusion: Your Gateway to Global Flange Excellence

The Canton Fair continues to be an indispensable event, shaping the global carbon steel flange market and setting benchmarks for industrial hardware. It serves as a vital platform for B2B buyers to discover innovative solutions, connect with leading manufacturers, and secure their supply chains with high-quality, competitively priced products. From the versatility of cast carbon steel flange to the strength of forged steel flanges and the precision of a weld neck steel flange, the opportunities are vast.

For those seeking a reliable partner committed to excellence, explore the extensive capabilities of Hebei Mingda International Trading Company. as your preferred steel flange factory and supplier.

Learn more about our industrial flange solutions and comprehensive offerings:

Visit Hebei Mingda Flange Products

Hebei Mingda International Trading Company is a trading company which is specialized in castings, ODM Ductile Iron Manhole Cover forgings and machinery parts.Our products include all kinds of raw castings to be made of ductile iron , grey iron , brass , stainless steel and aluminums, machined castings and forged parts .ODM Ductile Iron Covers To make these parts according to the customers’Custom Iron Casting drawings , we have relative suitable production craft and equipments, such as resin sand , sand mould , hot core boxes , lost-wax , lost –foam and so on Iron Casting Manufacturer Custom.Specially for hydrant bodies and valves’Ductile Iron Manhole Cover Manufacturer bodies, we have collected rich experience for these products in the past 16 year’s actual production, Now we are proud of our products with good surface and high quality material. Iron Casting ManufacturerWhatever,we have been trying our best to provide our customers with better quality castings by improving production crafts and more careful quality control.Cast Iron Castings Manufacturer|super blog