Inside China’s Aluminum Parts Machining: What Buyers Actually Get in 2025

If you’ve been shopping around for china aluminum parts machining, you’ve probably noticed two things: lead times are tightening, and expectations are rising. That’s the paradox. Automation has made tolerances tighter, yet real-world buyers still want flexibility, fair MOQs, and straightforward quality gates. I’ve toured more than a dozen plants; some over-promise. A few deliver consistently.

Trend check: lighter, tighter, greener

Across EV platforms, robotics, and machinery, buyers keep asking for thinner walls (≈1.5–2.0 mm), fewer secondary ops, and traceability that doesn’t slow production. To be honest, sustainability is no longer a “nice-to-have”: recycled alloy content and energy monitoring are being written into RFQs. Many customers say they’ll pay a small premium for verified porosity control and consistent anodizing color. I guess that’s the new normal.

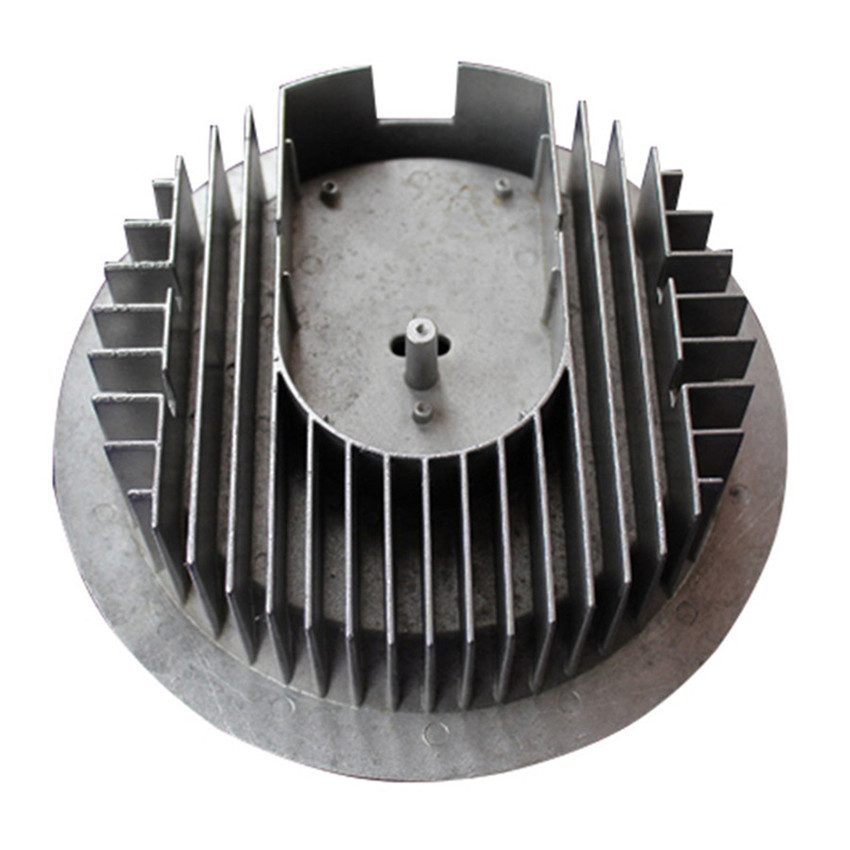

Product spotlight: OEM Custom Die Casting Aluminum Parts

Origin: Gelan Building, No.256 Xisanzhuang Street, Shijiazhuang, Hebei, China. Short Description: Basic Info — Die Casting Machine Type: Cold Chamber; Die Casting Method: Precision; Application: Machinery Parts; Machining: CNC Machining; Material: Aluminum; Surface Preparation: Polishing; Pressure Chamber: Vertical; Tolerance Grade: 8.

| Parameter | Specification (real-world use may vary) |

|---|---|

| Process | Cold-chamber precision die casting + CNC machining (3/4/5-axis) |

| Alloys | ADC12/A380 (die cast), 6061-T6 (machined ops), others on request |

| Tolerance | Grade 8 (≈ IT8/CT8); typical ±0.05–0.10 mm on criticals after CNC |

| Wall thickness | ≈1.5–3.5 mm, geometry-dependent |

| Surface | Polishing standard; anodizing, powder coat, chromate optional |

| QA & Testing | CMM, X-ray porosity, tensile per ASTM E8/E8M, salt spray 120–480 h |

| Tool/die life | ≈80k–120k shots (alloy and maintenance dependent) |

Process flow (what actually happens on the floor)

- Material pick: ADC12/A380 for casting; 6061-T6 billets for secondary mills.

- Tooling: DFM + moldflow, vertical pressure chamber setup, gating tuned for porosity ≤1%.

- Die casting: Cold-chamber shots with thermal control; real SPC on shot weight.

- CNC machining: Datum-first strategy; reaming/broach where needed; deburr standard.

- Finishes: Polishing standard; anodize color ΔE ≤ 2.0 target when specified.

- Testing: CMM 100% on A-keys; tensile coupons (UTS ADC12 ≈ 250–310 MPa); X-ray per lot; salt spray up to 480 h on coated parts.

- Packaging & traceability: QR-coded lots; COA + material certs attached.

Applications: machinery housings, robot gearcase covers, small EV motor brackets, UAV gimbals. Typical service life in the field? Around 5–10 years, depending on load cycles, coating, and environment.

Vendor comparison (quick reality check)

| Vendor | Certs | Typical tolerance | Lead time | MOQ | Notes |

|---|---|---|---|---|---|

| Mingda Metals | ISO 9001, IATF 16949 (stated) | ±0.05–0.10 mm after CNC | Tooling 3–5 wks; mass prod 2–4 wks | ≈500 pcs | X-ray per lot; PPAP/FAI on request |

| Coastal Supplier B | ISO 9001 | ±0.08–0.15 mm | 4–6 wks | 1,000 pcs | Limited moldflow |

| Boutique Shop C | ISO 9001 (pending) | ±0.05 mm (low volume) | 6–8 wks | ≈100 pcs | Good prototyping; pricier |

Customization, feedback, quick cases

Customization includes DFM, draft-angle optimization, thread inserts, and mixed finishing. One robotics customer told me, “Cycle time dropped 14% after gate redesign.” Another buyer noted more consistent flatness (0.1 mm/100 mm) after switching to china aluminum parts machining with X-ray gated control.

Case 1: an EV accessory maker moved from sand cast + mill to die casting + minor CNC; unit cost fell ≈19% and yield improved to 98.3%. Case 2: a drone brand demanded ΔE ≤ 2 anodize; after pre-anodize etch tuning, reject rate dropped under 1.5%—surprisingly fast win.

Standards and compliance (the boring part that saves you money)

Look for ISO 9001 and IATF 16949 when automotive traceability is in play. Dimensional checks aligned with ISO 2768; casting per GB/T 9438 or EN 1706; tensile per ASTM E8/E8M. For many buyers, that’s the difference between smooth PPAP and a month of firefighting. If your RFQ references china aluminum parts machining, spell out porosity class, salt spray hours, and critical datum callouts—vendors appreciate clarity.

Authoritative citations:

- ISO 9001:2015 Quality management systems.

- IATF 16949:2016 Automotive quality management.

- ASTM E8/E8M-22, Tension Testing of Metallic Materials.

- ISO 2768-1: General tolerances.

- GB/T 9438-2013, Aluminum alloy castings.

- EN 1706: Aluminum and aluminium alloys — Castings.

Hebei Mingda International Trading Company is a trading company which is specialized in castings, ODM Ductile Iron Manhole Cover forgings and machinery parts.Our products include all kinds of raw castings to be made of ductile iron , grey iron , brass , stainless steel and aluminums, machined castings and forged parts .ODM Ductile Iron Covers To make these parts according to the customers’Custom Iron Casting drawings , we have relative suitable production craft and equipments, such as resin sand , sand mould , hot core boxes , lost-wax , lost –foam and so on Iron Casting Manufacturer Custom.Specially for hydrant bodies and valves’Ductile Iron Manhole Cover Manufacturer bodies, we have collected rich experience for these products in the past 16 year’s actual production, Now we are proud of our products with good surface and high quality material. Iron Casting ManufacturerWhatever,we have been trying our best to provide our customers with better quality castings by improving production crafts and more careful quality control.Cast Iron Castings Manufacturer|super blog