OEM Custom Precision Aluminum Casting: an on-the-ground view from China

People often ask me where to start with

china aluminum casting.

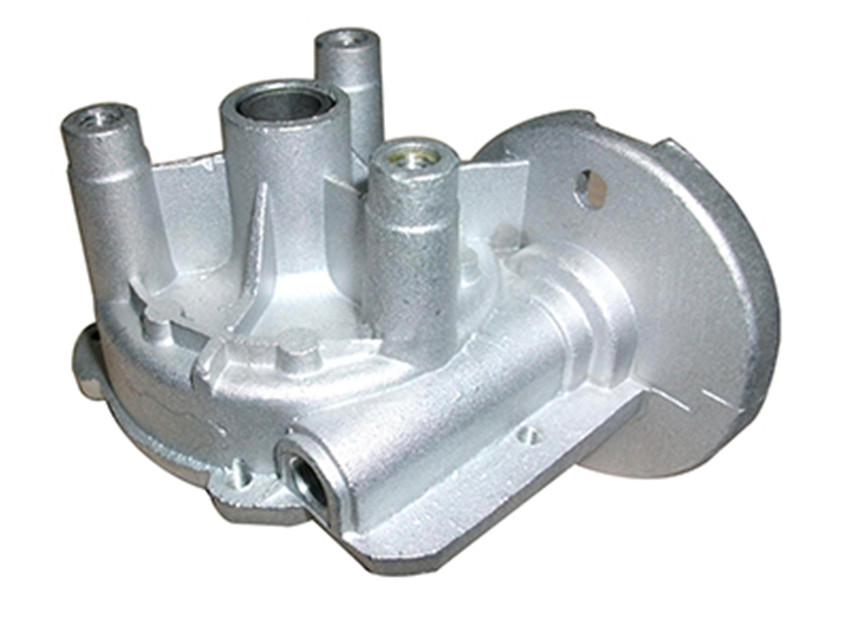

To be honest, it comes down to repeatable processes, data you can trust, and a factory that picks up the phone. This OEM Custom Precision Aluminum Casting line (origin: Gelan Building, No.256 Xisanzhuang Street, Shijiazhuang, Hebei, China) leans on cold-chamber die casting with CNC machining and polishing—bread-and-butter for machinery parts, but with some welcome nuance.

What’s trending now

- Lightweighting for EV and robotics—more structural castings, fewer weldments.

- Vacuum die casting and squeeze-cast hybrids to tame porosity (customers love this).

- Digital first-article reviews using CT or X-ray overlays—saves weeks, surprisingly.

- Recycled content tracking and EPDs to meet EU/US regulations.

Product snapshot and specs

Short version: cold-chamber precision die casting, then CNC, then polish. It’s the reliable combo many buyers expect from china aluminum casting.

| Parameter | Spec (≈ / real-world may vary) |

|---|---|

| Material | Aluminum alloys (A380/ADC12/A356 per application) |

| Die Casting Machine | Cold Chamber, Precision Die Casting |

| Machining | CNC 3–5 axis, GD&T capability |

| Surface | Polishing, optional anodizing/powder coat |

| Dimensional tolerance | ISO 8062-3 CT6–CT8 typical; CNC to ±0.05 mm ≈ |

| Porosity grade | Per ASTM E155 reference levels; vacuum option for tighter spec |

| Mechanical (A380) | UTS ≈ 290–320 MPa; YS ≈ 150–180 MPa; Elong. ≈ 2–4% |

| Service life (die) | ≈ 80,000–150,000 shots depending on part/maintenance |

| Compliance | ISO 9001, IATF 16949 (program dependent), RoHS/REACH |

Process flow (how parts actually get done)

- DFM + tool design (gates/vents; warpage sims if needed).

- Tooling build and sampling (FAI with CMM reports).

- Alloy melt control (degassing, hydrogen check), then cold-chamber shot.

- Trimming/deburring; heat treatment where alloy allows (A356 more than A380).

- CNC finishing, thread forming; polishing or anodizing.

- Inspection: X-ray per ASTM E155, leak test, dimensional per ISO 8062-3.

- Packaging and PPAP (auto) or FAIR (aero-like) on request.

Where these parts go

Machinery housings, EV motor mounts, drone frames, 5G enclosures, pump bodies—classic china aluminum casting territory. One HVAC client told me, “the leak rates finally dropped below 1% after we switched to vacuum shots.” Music to any quality manager’s ears.

Vendor snapshot (what buyers compare)

| Vendor type | Typical certs | Strengths | Risks | MOQ / Lead time | Indicative cost |

|---|---|---|---|---|---|

| Integrated factory (e.g., Mingda Metals) | ISO 9001, IATF 16949 (program) | Tooling + CNC in-house; faster PPAP | Slightly higher NRE | MOQ ≈ 500–1,000; 3–6 weeks | $$ (balanced) |

| Small job shop | ISO 9001 (varies) | Flexible, low MOQ | Capacity swings; documentation gaps | MOQ ≈ 100–300; 4–8 weeks | $ (lower) |

| Trading company | Depends on partner plant | Sourcing breadth, English support | Opaque root cause, margin layer | MOQ varies; 5–9 weeks | $$$ (varies) |

Case note and customization

An EU robotics customer requested ±0.03 mm on bearing seats; the team added localized chill vents and post-cast reaming. Scrap fell below 2%, and cycle time only crept by ≈ 6%. Customization usually means: alloy selection (A356 vs ADC12), vacuum gating for porosity control, and post-cast impregnation when the design won’t budge.

Testing, standards, and data

- Die cast spec: ASTM B85; China GB/T 9438 for aluminum alloy die castings.

- Tolerance: ISO 8062-3; Radiography: ASTM E155; Salt spray: ASTM B117 (coated parts).

- Automotive quality: IATF 16949; general QMS: ISO 9001.

- Typical test set: CMM FAI, X-ray (critical ribs/bosses), leak test to 0.5–1.0 bar, hardness ≈ 75–90 HB.

If you’re comparing china aluminum casting quotes, ask for X-ray grades, gate/vent photos, and a sample CMM ballooned drawing. You’ll spot real process control quickly.

References

Hebei Mingda International Trading Company is a trading company which is specialized in castings, ODM Ductile Iron Manhole Cover forgings and machinery parts.Our products include all kinds of raw castings to be made of ductile iron , grey iron , brass , stainless steel and aluminums, machined castings and forged parts .ODM Ductile Iron Covers To make these parts according to the customers’Custom Iron Casting drawings , we have relative suitable production craft and equipments, such as resin sand , sand mould , hot core boxes , lost-wax , lost –foam and so on Iron Casting Manufacturer Custom.Specially for hydrant bodies and valves’Ductile Iron Manhole Cover Manufacturer bodies, we have collected rich experience for these products in the past 16 year’s actual production, Now we are proud of our products with good surface and high quality material. Iron Casting ManufacturerWhatever,we have been trying our best to provide our customers with better quality castings by improving production crafts and more careful quality control.Cast Iron Castings Manufacturer|super blog