If you’ve ever stood on a refinery deck at dawn and watched maintenance crews hustle, you know why a reliable weld neck flange factory matters. Deadlines don’t wait. Neither do pressure cycles or chloride-heavy spray. I’ve toured enough shops to say: subtle differences in forging, heat treatment, and inspection turn into very real uptime later.

What’s moving the market

Two converging trends: traceable metallurgy (PMI on every heat) and tougher global specs. Honestly, buyers are asking for ASME B16.5 dimensional control with EN 1092-1 face finish, plus NACE MR0175 awareness when sour service lurks. Stainless long weld necks are hot in hydrogen-ready retrofits and desalination—corrosion doesn’t negotiate.

Product snapshot: Stainless Steel Long Weld Neck Flange

Origin: Gelan Building, No.256 Xisanzhuang Street, Shijiazhuang, Hebei, China. Port: Tianjin. Transport by ocean, land, air. Packaging is the usual export crate with rust-inhibiting wrap—simple but it works.

| Standard | DIN, GB, JIS, ANSI/ASME, GOST |

| Material | Stainless (ASTM A182 F304/F316; others on request) |

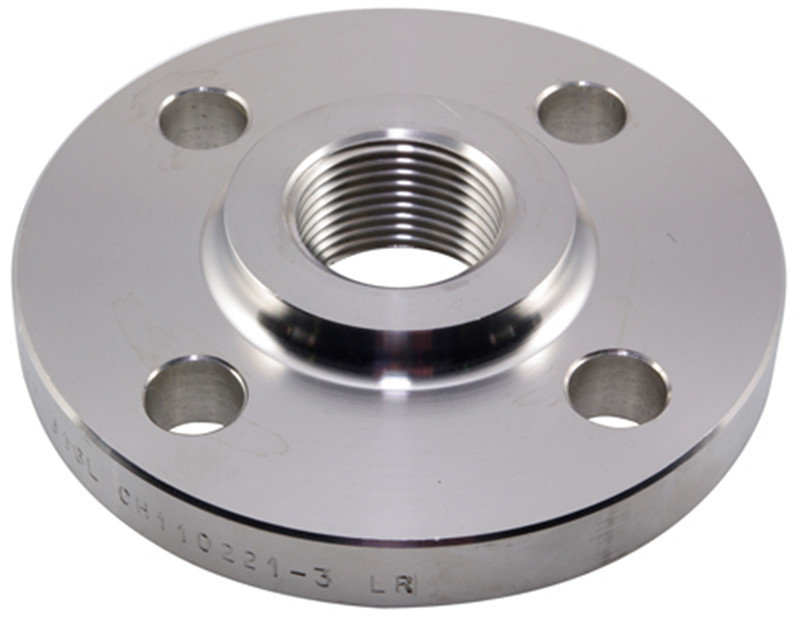

| Type / Structure | Long Weld Neck, lateral; forged, RF face |

| Sizes / Ratings | NPS 1/2–24; Class 150–1500 (≈ DN15–DN600, PN20–PN260) |

| Face Finish | Ra 3.2–6.3 µm typical (real-world may vary) |

| Testing | PMI 100%, UT on forgings, hydrostatic ≈1.5× design pressure, PT on sealing surfaces |

| Certs | EN 10204 3.1 MTC; ISO 9001 QMS |

How they’re made (the short version)

Materials: AOD/ESR-refined stainless billets. Methods: open-die forging, normalization/solution treatment, CNC machining, serrated gasket face. Testing: PMI gun on every piece, UT per ASTM/A388 (forging), hydro test per ISO 5208, dimension check to ASME B16.5/B16.47. Service life? In clean steam, I’ve seen 25–30 years; in chloride brine, plan conservatively for 10–15 with proper alloy selection.

Where they go

Oil & gas manifolds, chemical dosing skids, power plant condensate lines, shipbuilding, desalination, and increasingly, hydrogen pilot loops. The long neck smooths stress at the weld—less turbulence, better fatigue behavior. Many customers say installation is “boringly predictable,” which is what you want.

Vendor comparison (real-world buyer notes)

| Vendor | Certifications | Lead Time | MOQ | Traceability | Notes |

|---|---|---|---|---|---|

| Mingda Metals (weld neck flange factory) | ISO 9001; EN 10204 3.1 | ≈ 15–25 days | Flexible | Heat-to-piece | Solid PMI and UT reports included |

| Local Distributor | Varies | Stock or 2–6 weeks | Small OK | Partial | Fast for common sizes; pricey |

| Anonymous Trading Co. | Unclear | Unclear | High | Limited | Check MTC authenticity carefully |

Customization and QA

Options: special neck length, RTJ faces, HAZ pickling, electropolish, NACE-compliant chemistries, and low-ferrite weld overlays for harsh chlorides. Test data I reviewed showed hydro at 1.5× rating for 60 min with zero weep; face flatness within 0.3 mm on 12-inch Class 600—nice work.

Quick case notes

- Desal retrofit, MENA: 316L long weld necks cut shutdown by ≈18% year-on-year; maintenance cited smoother alignment and fewer gasket issues.

- Bioethanol plant, EU: DIN pattern with RTJ face; customer feedback—“no flange leaks in first 9 months,” which, frankly, is what you should expect.

If you’re vetting a weld neck flange factory, ask for: heat maps, UT technique sheets, surface-finish records, and a sample MTC. Simple checks, big payoff.

Standards referenced

- [1] ASME B16.5 – Pipe Flanges and Flanged Fittings

- [2] EN 1092-1 – Flanges and their joints

- [3] ASTM A182 – Forged or Rolled Alloy-Stainless Steel Pipe Flanges

- [4] ISO 5208 – Industrial valves—Pressure testing

- [5] ISO 9001 – Quality management systems

Hebei Mingda International Trading Company is a trading company which is specialized in castings, ODM Ductile Iron Manhole Cover forgings and machinery parts.Our products include all kinds of raw castings to be made of ductile iron , grey iron , brass , stainless steel and aluminums, machined castings and forged parts .ODM Ductile Iron Covers To make these parts according to the customers’Custom Iron Casting drawings , we have relative suitable production craft and equipments, such as resin sand , sand mould , hot core boxes , lost-wax , lost –foam and so on Iron Casting Manufacturer Custom.Specially for hydrant bodies and valves’Ductile Iron Manhole Cover Manufacturer bodies, we have collected rich experience for these products in the past 16 year’s actual production, Now we are proud of our products with good surface and high quality material. Iron Casting ManufacturerWhatever,we have been trying our best to provide our customers with better quality castings by improving production crafts and more careful quality control.Cast Iron Castings Manufacturer|super blog