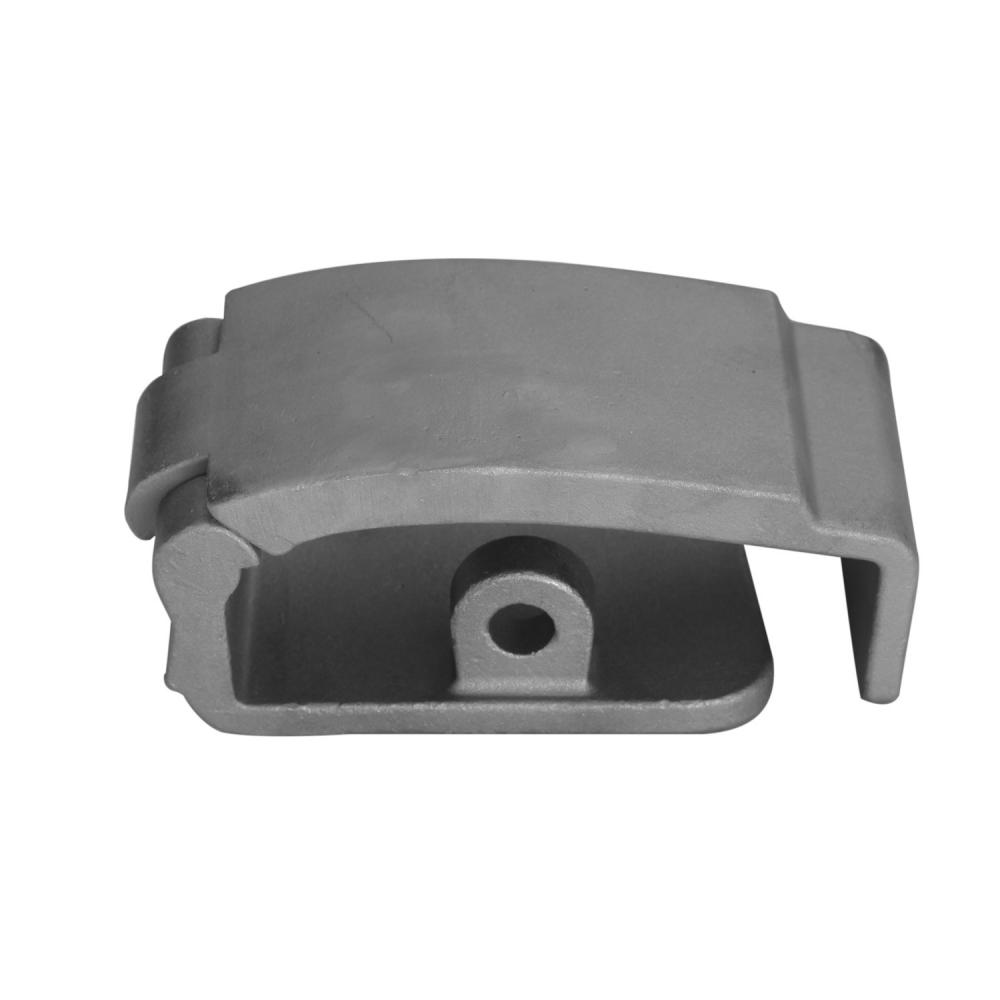

OEM/ODM Custom Stainless Steel Casting Part: field notes from the shop floor

If you’ve ever stood next to a wax tree on a Monday morning, coffee in one hand and calipers in the other, you know the satisfaction of a well-made casting part. This piece from Mingda Metals comes out of Gelan Building, No.256 Xisanzhuang Street, Shijiazhuang, Hebei, China—an address I’ve actually scribbled into my notebook because shipments arriving from there tend to be punctual, which, frankly, saves headaches.

Why this casting part keeps popping up in RFQs

Trend-wise, stainless investment castings are climbing in sectors that demand cleanability and corrosion resistance—think food equipment, pumps/valves, and marine hardware. The mix here—thermal gravity pour, lost-wax process, polished finish to ≈Ra6.3—hits that sweet spot between precision and cost. To be honest, a lot of buyers underestimate how much consistency you get when wax gating is disciplined and shell thickness is tuned. This shop seems to get it.

Key specifications at a glance

| Process | Lost-wax (investment) + thermal gravity pour; pressure-assisted molding where applicable |

| Material | Stainless steel (e.g., 304/CF8, 316/CF8M, 17-4PH) per ASTM A743/A744 options |

| Surface finish | Polished; surface roughness ≈ Ra6.3 (real-world use may vary with geometry) |

| Dimensional tolerance | Typically ISO 8062 CT6–CT8 after process capability study |

| Typical tensile strength | ≈520–620 MPa (304/316 references); 17-4PH heat-treated higher |

| Post-processing | Deburr, polishing, passivation (ASTM A967), machining as needed |

Process flow (the condensed, real-world version)

DFM review → wax pattern → tree assembly → ceramic shell building (5–8 coats) → dewax → thermal gravity pour → knockout → cutoff & grind → heat treat (if spec’d) → CNC touch-ups → polishing → passivation → inspection → packaging. NDT: liquid penetrant (PT) and, where magnets help, MT; dimensional checks to ISO 8062; material certs per EN 10204 3.1. Salt-spray (ASTM B117) available for finish validation on request.

Applications and advantages

- Industries: pump/valve bodies, food/chemical equipment, medical brackets (non-implant), marine fittings, agricultural machinery.

- Advantages: tight geometry replication, better buy-to-fly than billet machining, corrosion resistance, consistent cosmetics after polishing.

- Service life: around 10–15 years in moderate corrosion; marine splash zones vary—passivation and grade selection matter a lot.

Vendor landscape (quick comparison)

| Vendor | Strengths | Typical lead time | Certs |

|---|---|---|---|

| Mingda Metals (China) | OEM/ODM flexibility, polished finish control, responsive DFM | ≈4–6 weeks after tooling | ISO 9001; PPAP on request; EN 10204 3.1 |

| Foundry B (Asia) | Cost-competitive on large batches | ≈6–8 weeks | ISO 9001 |

| Foundry C (EU) | Traceability depth, niche alloys | ≈5–7 weeks | ISO 9001, IATF 16949 (select lines) |

Customization, testing, and what buyers actually ask

Customization usually starts with a STEP file and a tolerance map. Many customers say, “Can you hold ±0.1 mm here?”—sometimes yes, sometimes we tweak the datum strategy or add a light finish pass. Test data I’ve seen includes PMI for grade verification, hardness checks (HB/HRB), and PT results logged to part number. Documentation set often ships with 3.1 certs; for automotive, PPAP levels are available when required.

Mini case study

A European pump OEM needed a 316 casting part with internal passages that machining alone would have blown the budget on. After a two-iteration DFM (minor fillet changes, smarter gating), CT7 was met, leak testing passed first shot, and the polish hit Ra≈6.0. Feedback was short and sweet: “Dimensional drift is basically gone.” I guess that’s the best kind of email.

Bottom line

If your spec leans on corrosion resistance, tidy cosmetics, and reasonable tolerances, this casting part format is a practical, production-friendly choice—especially with clear DFM, material certs, and a finish plan baked in.

Authoritative citations

- ISO 8062-3: Geometrical product specifications (GPS) — Tolerances for castings. https://www.iso.org/standard/69592.html

- ASTM A743/A743M: Standard Specification for Castings, Iron-Chromium, Iron-Chromium-Nickel, Corrosion Resistant. https://www.astm.org/a0743_a0743m-19.html

- ASTM A967/A967M: Chemical Passivation Treatments for Stainless Steel Parts. https://www.astm.org/a0967_a0967m-17.html

- EN 10204: Metallurgical inspection documents (3.1). https://standards.iteh.ai/catalog/standards/cen/4a3a0e2b-6b2a-4d5f-8d5e-7c5e5f2a0e3e/en-10204-2004

- ASTM B117: Standard Practice for Operating Salt Spray (Fog) Apparatus. https://www.astm.org/b0117-19.html

Hebei Mingda International Trading Company is a trading company which is specialized in castings, ODM Ductile Iron Manhole Cover forgings and machinery parts.Our products include all kinds of raw castings to be made of ductile iron , grey iron , brass , stainless steel and aluminums, machined castings and forged parts .ODM Ductile Iron Covers To make these parts according to the customers’Custom Iron Casting drawings , we have relative suitable production craft and equipments, such as resin sand , sand mould , hot core boxes , lost-wax , lost –foam and so on Iron Casting Manufacturer Custom.Specially for hydrant bodies and valves’Ductile Iron Manhole Cover Manufacturer bodies, we have collected rich experience for these products in the past 16 year’s actual production, Now we are proud of our products with good surface and high quality material. Iron Casting ManufacturerWhatever,we have been trying our best to provide our customers with better quality castings by improving production crafts and more careful quality control.Cast Iron Castings Manufacturer|super blog