Unlocking Global Opportunities: Top Precision Casting Manufacturers from China at the Canton Fair

Introduction: The Canton Fair – Your Gateway to Industrial Excellence

The Canton Fair, officially known as the China Import and Export Fair, stands as an unparalleled global sourcing and export hub, particularly for industrial materials and high-value components like precision casting products. Twice a year, this colossal event transforms Guangzhou into an international marketplace, drawing B2B decision-makers from every corner of the globe. For industries reliant on robust, meticulously engineered components, the Canton Fair is not just an exhibition; it’s a strategic imperative.

In the rapidly evolving landscape of manufacturing, the fair offers an invaluable platform to discover the latest innovations, establish critical supply chain connections, and source high-quality industrial hardware, especially in the realm of advanced metal fabrication. For businesses seeking reliable partners for oem precision casting, this event provides direct access to China’s leading manufacturers, showcasing their capabilities in producing complex, high-tolerance components that meet stringent international standards. It’s where the future of industrial sourcing in sectors like automotive, aerospace, construction, and general machinery truly begins.

Industry Trend Spotlight: Navigating the Future of Precision Casting

The precision casting industry is currently undergoing a significant transformation, driven by several key global trends. Advanced material composites are pushing the boundaries of what’s possible, leading to lighter, stronger, and more durable components. Concurrently, there’s an increasing demand for specialized and high-performance fasteners and components, particularly those crafted from materials like stainless steel precision casting, known for its corrosion resistance and strength. This shift caters to the stringent requirements of modern applications across various sectors.

Sustainability in metal production is also gaining unprecedented global attention. Manufacturers are investing in greener processes, reducing waste, and improving energy efficiency, aligning with international environmental goals. Furthermore, the integration of smart manufacturing techniques for quality control—from IoT-enabled monitoring to AI-driven inspection—is revolutionizing how stainless steel casting precision casting products are made, ensuring unparalleled consistency and reliability.

Market Dynamics and Emerging Focus Areas:

- Steady Growth in Construction and Infrastructure: This sector continues to fuel demand for robust, high-integrity metal components, including a wide array of precision casting parts for heavy machinery, structural elements, and utility systems.

- Increasing Demand for High-Performance and Specialized Materials: Industries like aerospace, medical, and marine require materials that can withstand extreme conditions, making advanced alloys and specialized stainless steel precision casting products indispensable.

- Ongoing Supply Chain Optimization Efforts: Businesses are constantly seeking efficiencies, reliability, and cost-effectiveness in their sourcing, positioning China as a critical partner due to its vast manufacturing ecosystem and logistical capabilities.

- Rise of Digital B2B Procurement Platforms: The digital transformation is enabling easier access to global suppliers, augmenting traditional trade fairs and expanding reach for buyers interested in oem precision casting.

Beyond these trends, emerging focus areas for B2B decision-makers include enhancing supply chain resilience in an unpredictable global economy, ensuring rigorous quality assurance in every international transaction, embracing sustainable sourcing practices, and always seeking competitive industrial solutions that deliver both value and performance. The Canton Fair provides a unique lens through which to observe and engage with these pivotal industry shifts.

Profiles of Leading Companies: Innovators in Precision Casting

Hebei Mingda International Trading Company: Your Partner in Precision

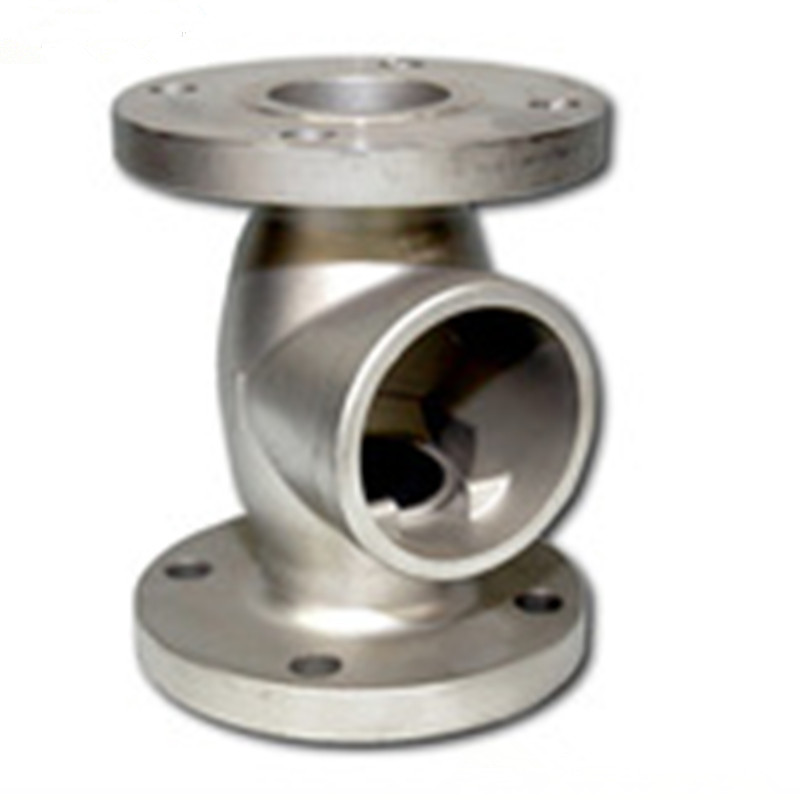

At the forefront of China’s industrial export prowess, Hebei Mingda International Trading Company consistently stands out at the Canton Fair. Renowned for its comprehensive approach to industrial components and materials, Hebei Mingda specializes in delivering exceptional OEM precision casting solutions that cater to a diverse array of global industries. Their expertise in stainless steel precision casting is particularly noteworthy, offering unparalleled quality and customization for complex applications.

What truly sets Hebei Mingda apart is their broad product portfolio, encompassing a wide range of metals and industrial hardware, all backed by a strong international trade network. This robust network ensures seamless communication, efficient logistics, and a deep understanding of varied market demands. Their supply chain management capabilities are second to none, providing clients with consistent quality, competitive pricing, and – critically – timely delivery, even for the most intricate stainless steel casting precision casting projects.

Hebei Mingda’s unwavering commitment to quality is evident in every product, ensuring that each stainless steel precision casting product meets rigorous international standards. They understand that for B2B decision-makers, reliability and precision are paramount. By leveraging advanced manufacturing techniques and strict quality control protocols, they provide bespoke casting solutions that are both cost-effective and engineered for superior performance.

To explore their extensive range of custom stainless steel precision casting products and learn how Hebei Mingda can support your next project, visit their dedicated product page: Hebei Mingda OEM Custom Stainless Steel Precision Casting Products.

Other Noteworthy Players in the Precision Casting Arena

Beyond specialized manufacturers, the Canton Fair also features a broad spectrum of global industrial material distributors and other export-oriented Chinese trading companies. These entities often act as vital bridges, connecting buyers with a multitude of factories specializing in various aspects of metal and precision casting, including high-volume oem precision casting and bespoke stainless steel casting precision casting solutions.

Many of these companies showcase their capabilities in specialized fastener manufacturing, general industrial components, and a wide array of raw and semi-finished metal products. Their presence underscores China’s dominant role in the global industrial supply chain, offering competitive advantages in terms of scale, cost-efficiency, and technological advancement in precision casting and related metalworking fields. They are constantly innovating, introducing new materials and processes to meet the evolving demands for performance and durability in components across all industries.

Market Outlook & Opportunities: The Future of Industrial Solutions

The outlook for the precision casting market remains robust, driven by persistent global infrastructure development, technological advancements in end-user industries, and a continued push for higher performance and efficiency. Buyer demand is increasingly focused on customized, application-specific oem precision casting solutions that offer superior material properties and complex geometries. There’s a growing emphasis on traceability and material certification, especially for critical stainless steel precision casting products used in sectors where safety and reliability are paramount.

Key Opportunities for Innovation and Growth:

- Automation in Precision Casting: The adoption of robotics and automated processes in precision casting foundries is enhancing efficiency, reducing human error, and ensuring consistent product quality. This is particularly beneficial for high-volume production of intricate components.

- Smart Manufacturing Integration: Leveraging data analytics, AI, and IoT devices within the manufacturing process allows for real-time monitoring, predictive maintenance, and precise quality control, optimizing the production of stainless steel casting precision casting from start to finish.

- Sustainable Production Practices: As environmental concerns grow, manufacturers who prioritize eco-friendly processes—such as recycling, waste reduction, and energy-efficient operations—will gain a significant competitive edge. This commitment is becoming a critical factor for B2B buyers seeking responsible sourcing partners for stainless steel precision casting products.

These opportunities highlight a future where precision casting is not just about forming metal, but about intelligent, sustainable, and highly specialized manufacturing. Chinese manufacturers, often early adopters of these technologies, are well-positioned to meet these evolving demands.

Buyer/Business Takeaways: Strategizing for Success in Precision Casting

For B2B decision-makers, understanding the dynamic landscape of precision casting is key to maintaining a competitive edge. Investing in high-quality precision casting components, particularly those made through advanced stainless steel precision casting processes, makes sound business sense. These components are critical for enhancing product performance, ensuring longevity, and ultimately reducing long-term operational costs across a multitude of applications—from heavy industry to specialized equipment.

Tips for Adopting or Partnering with Chinese Manufacturers:

- Conduct Thorough Due Diligence: Always perform background checks, factory audits, and verify certifications, especially for critical oem precision casting projects. Reputable suppliers like Hebei Mingda will welcome such scrutiny.

- Emphasize Clear Communication: Provide detailed specifications, drawings, and material requirements upfront for any stainless steel casting precision casting order to minimize misunderstandings and ensure the final product meets your exact needs.

- Leverage Trade Platforms: Utilize events like the Canton Fair, both physically and virtually, to meet potential partners face-to-face, discuss capabilities, and inspect samples of stainless steel precision casting products.

- Prioritize Long-Term Relationships: Building trust and a strong rapport with your Chinese manufacturing partner can lead to better pricing, improved service, and more collaborative innovation over time.

Future-Proofing Your Sourcing Strategy:

To future-proof your business, consider diversifying your sourcing channels, not just for raw materials but also for specialized components like precision casting parts. Embrace digital tools for procurement and supply chain management to enhance transparency and efficiency. Most importantly, integrate sustainability and ethical practices into your sourcing criteria, choosing partners who align with these values. By focusing on quality, innovation, and strategic partnerships, businesses can navigate the complexities of global sourcing and ensure a resilient supply of high-performance precision casting solutions.

Conclusion: Canton Fair and the Future of Precision Casting

The Canton Fair remains an indispensable event for anyone involved in the global industrial supply chain, particularly for those seeking excellence in precision casting. It serves as a vital platform where innovative Chinese manufacturers, like Hebei Mingda International Trading Company, showcase their advanced capabilities in OEM precision casting, stainless steel precision casting, and the production of a wide range of high-quality stainless steel precision casting products. The fair continues to shape the global industrial market by fostering new partnerships, driving technological adoption, and setting benchmarks for quality and sustainability.

Ready to elevate your sourcing strategy for industrial metals and precision casting components? Discover why B2B decision-makers worldwide trust Hebei Mingda International Trading Company for their custom manufacturing needs.

Explore Hebei Mingda’s OEM Custom Stainless Steel Precision Casting Products Now!

Hebei Mingda International Trading Company is a trading company which is specialized in castings, ODM Ductile Iron Manhole Cover forgings and machinery parts.Our products include all kinds of raw castings to be made of ductile iron , grey iron , brass , stainless steel and aluminums, machined castings and forged parts .ODM Ductile Iron Covers To make these parts according to the customers’Custom Iron Casting drawings , we have relative suitable production craft and equipments, such as resin sand , sand mould , hot core boxes , lost-wax , lost –foam and so on Iron Casting Manufacturer Custom.Specially for hydrant bodies and valves’Ductile Iron Manhole Cover Manufacturer bodies, we have collected rich experience for these products in the past 16 year’s actual production, Now we are proud of our products with good surface and high quality material. Iron Casting ManufacturerWhatever,we have been trying our best to provide our customers with better quality castings by improving production crafts and more careful quality control.Cast Iron Castings Manufacturer|super blog