The Imperative Role of OEM Precision Casting in Modern Manufacturing

In the highly specialized world of B2B manufacturing, the demand for components that offer exceptional accuracy, material integrity, and cost-efficiency is paramount. This is where oem precision casting stands out as a critical manufacturing process. It enables the production of intricate parts with complex geometries and superior surface finishes directly from molten metal, significantly reducing the need for extensive secondary machining. Our focus today is on the strategic advantages and technical intricacies of this method, particularly concerning stainless steel, a material renowned for its robustness and corrosion resistance. This process is indispensable across numerous industries, ensuring high-performance components that meet stringent operational requirements.

OEM precision casting, also known as investment casting or lost-wax casting, is a sophisticated process that facilitates the creation of highly accurate and repeatable parts. When applied to stainless steel, the result is stainless steel precision casting products that offer unparalleled durability, resistance to harsh environments, and excellent mechanical properties. This makes them ideal for demanding applications where reliability and longevity are non-negotiable.

Industry Trends and Market Dynamics in Precision Casting

The global precision casting market is experiencing robust growth, driven by increasing demand from the aerospace, automotive, medical, and energy sectors. Projections indicate the market size will exceed USD 20 billion by 2027, with a compound annual growth rate (CAGR) of over 6%. This expansion is fueled by the continuous need for lightweight, high-strength components capable of operating under extreme conditions. Innovations in automation, advanced simulation software for mold design, and the development of new alloy compositions are further enhancing the capabilities and efficiency of oem precision casting. There is a notable trend towards customization and smaller batch production, requiring manufacturers to be more agile and versatile in their offerings, particularly for stainless steel casting precision casting.

Furthermore, sustainability and environmental concerns are shaping industry practices. Manufacturers are increasingly adopting eco-friendly processes, optimizing material usage, and enhancing energy efficiency in their casting operations. The emphasis on higher material utilization and reduced waste makes precision casting a particularly attractive option compared to traditional machining from solid blocks, aligning with modern manufacturing’s green initiatives.

Detailed Process Flow: The Art and Science of OEM Precision Casting

The production of high-quality components through oem precision casting involves a meticulously controlled, multi-stage process. This method, rooted in ancient lost-wax techniques, has been refined with modern engineering to achieve unparalleled precision and material integrity.

- Wax Pattern Creation: A master die, typically machined from aluminum or steel, is used to inject wax to create an exact replica of the desired component. This wax pattern accurately reproduces all geometric features and critical dimensions.

- Wax Tree Assembly: Multiple wax patterns are attached to a central wax sprue, forming a ‘tree’ assembly. This sprue acts as a conduit for molten metal during the pouring stage.

- Ceramic Shell Building: The wax tree is repeatedly dipped into a ceramic slurry and then coated with refractory sand. This process is repeated several times, with drying periods in between, to build a robust ceramic shell around the wax patterns.

- Dewaxing (Autoclave): The ceramic shell, with the wax tree inside, is heated in an autoclave. The wax melts and drains out, leaving a hollow ceramic mold. The recovered wax can often be recycled.

- Shell Firing and Preheating: The ceramic mold is fired at extremely high temperatures (typically 1000-1200°C) to burn out any residual wax, strengthen the ceramic, and preheat the mold for casting. Preheating prevents thermal shock when molten metal is introduced.

- Metal Pouring: Molten metal, such as various grades of stainless steel (e.g., 304, 316, 17-4PH), is poured into the hot ceramic mold. The high preheat temperature ensures excellent flow and filling of intricate details.

- Knockout and Cut-off: Once the metal has solidified and cooled, the ceramic shell is mechanically removed (knocked out). Individual cast parts are then cut off the central sprue.

- Grinding and Finishing: Gate attachment points are ground smooth, and initial surface finishing is performed.

- Heat Treatment: Depending on the alloy and desired mechanical properties, parts undergo various heat treatment processes (e.g., annealing, solution treatment, precipitation hardening) to optimize hardness, strength, and corrosion resistance.

- CNC Machining & Secondary Operations: For critical dimensions and tight tolerances, parts may undergo subsequent CNC machining, drilling, tapping, or specialized surface treatments (e.g., passivation, electro-polishing).

- Inspection and Testing: Comprehensive quality control measures are applied, including dimensional checks, non-destructive testing (NDT) like X-ray, ultrasonic, or dye penetrant inspection, and mechanical property testing. Compliance with standards such as ISO 9001, ASTM A743/A744, and ANSI B16.34 is meticulously verified.

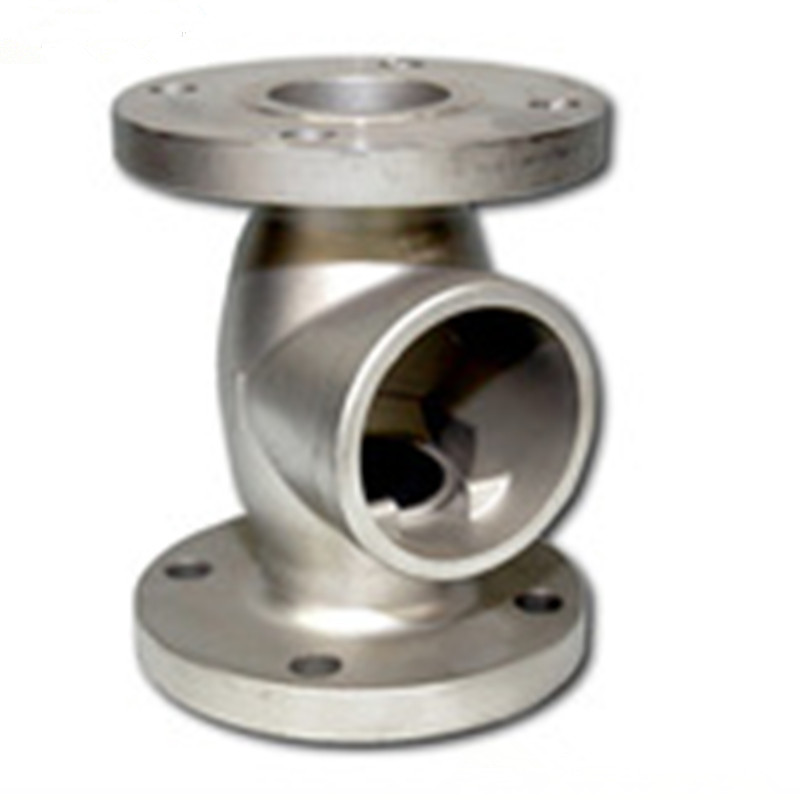

Target industries for these stainless steel precision casting products include petrochemical (valves, pump components), metallurgy (high-temperature parts), water supply & drainage (fittings, impellers), marine (corrosion-resistant hardware), and food & beverage (sanitary fittings). The inherent advantages of this process, such as superior corrosion resistance, high dimensional accuracy (tolerances often within ±0.005 inches/inch), and significantly reduced material waste, contribute to extended service life and energy efficiency in complex systems.

Technical Specifications and Material Capabilities

The success of oem precision casting hinges on strict adherence to technical specifications and judicious material selection. Stainless steels are preferred for their excellent balance of mechanical properties, corrosion resistance, and aesthetic appeal. Common grades include:

- 304/304L Stainless Steel: Widely used austenitic grade, offering good corrosion resistance and weldability, suitable for general purpose applications.

- 316/316L Stainless Steel: Superior corrosion resistance, particularly against chlorides, due to molybdenum content, ideal for marine, chemical, and food processing environments.

- 17-4PH Stainless Steel: A precipitation-hardening martensitic stainless steel known for high strength and hardness, excellent for aerospace and industrial applications.

- Duplex Stainless Steels (e.g., 2205): Combine high strength and corrosion resistance, particularly stress corrosion cracking, suitable for offshore and aggressive chemical environments.

Typical Stainless Steel Precision Casting Product Specifications

| Parameter | Typical Range/Value | Notes |

|---|---|---|

| Material Grades | 304, 316, 17-4PH, Duplex, other custom alloys | ASTM A743/A744 compliant |

| Dimensional Tolerances | ±0.005 in/in (first inch), ±0.003 in/in (subsequent) | Geometric tolerances as per ISO 2768-mH |

| Surface Finish (as-cast) | Ra 1.6 – 3.2 µm (63 – 125 RMS) | Can be improved with secondary polishing |

| Maximum Part Weight | From a few grams up to 50 kg (110 lbs) | Varies by foundry capabilities |

| Minimum Wall Thickness | 0.060 inches (1.5 mm) | Achievable with specific design considerations |

| Testing & Inspection | CMM, Spectrometer, Hardness Tester, NDT (RT, UT, PT, MT) | Per ISO, ASTM, or client-specific standards |

Technical Advantages of Stainless Steel Precision Casting

The technical advantages offered by stainless steel precision casting are numerous and directly contribute to superior product performance and significant cost efficiencies for B2B clients.

- Superior Dimensional Accuracy: Compared to sand casting, investment casting delivers much tighter tolerances, often eliminating or drastically reducing subsequent machining operations. This is crucial for components requiring precise fits.

- Excellent Surface Finish: The ceramic shell provides a fine surface finish (typically Ra 1.6-3.2 µm), which is significantly smoother than other casting methods. This is vital for aesthetic components or those requiring reduced friction.

- Design Freedom and Complexity: This process allows for the creation of highly complex geometries, intricate internal passages, thin walls, and sharp details that are difficult or impossible to achieve with other manufacturing methods. This unlocks innovative product designs.

- Material Versatility: A wide range of ferrous and non-ferrous alloys, including various grades of stainless steel, can be cast, allowing for optimal material selection based on specific application requirements (e.g., strength, corrosion resistance, heat resistance).

- Reduced Waste and Cost Efficiency: Near-net-shape casting minimizes material waste, as less material needs to be removed through machining. For complex parts, the reduction in machining time and material usage often makes precision casting the most cost-effective solution.

- Exceptional Corrosion Resistance: Stainless steel components produced via precision casting retain their inherent resistance to rust, staining, and pitting in various corrosive environments, ensuring long-term performance and reliability.

Application Scenarios and Industry Impact

The versatility and high performance of stainless steel precision casting products make them indispensable across a broad spectrum of industries, solving critical engineering challenges and enhancing operational efficiency.

- Petrochemical Industry: Components like valve bodies, pump impellers, and pipe fittings made from corrosion-resistant 316L stainless steel are essential for handling aggressive chemicals and high-pressure fluids, ensuring safety and preventing costly leaks. Their long service life reduces maintenance downtime.

- Automotive and Heavy Machinery: For engine components, transmission parts, and structural brackets, precision castings offer high strength-to-weight ratios and complex geometries crucial for performance and fuel efficiency. Examples include turbocharger components and hydraulic system parts.

- Medical Devices: Surgical instruments, orthopedic implants, and dental prosthetics demand extremely high levels of precision, biocompatibility, and surface finish. Stainless steel precision casting excels in meeting these stringent requirements, often using medical-grade alloys.

- Aerospace and Defense: For turbine blades, structural airframe components, and weapon system parts, precision castings in superalloys or high-strength stainless steels offer lightweight solutions with superior performance under extreme temperatures and stresses.

- Food and Beverage Processing: Sanitary fittings, pump housings, and conveyor components require smooth, non-porous surfaces that are easy to clean and resist bacterial growth. 304L and 316L stainless steel castings are ideal for these applications due to their exceptional hygiene and corrosion resistance.

These scenarios underscore how precision casting, particularly with stainless steel, delivers not just parts, but integrated solutions that contribute to energy saving through optimized designs, enhanced corrosion resistance for longevity, and overall operational reliability.

Customized Solutions and Design Partnership

At the heart of effective oem precision casting services lies the ability to offer fully customized solutions. Our approach begins with a comprehensive understanding of the client’s specific application, performance requirements, and environmental conditions. This collaborative process ensures that the final product is not merely a component, but a perfectly engineered solution.

- Design for Manufacturability (DFM): Our engineering team works closely with clients, leveraging CAD/CAM and simulation tools to optimize part design for the investment casting process. This includes suggesting modifications to improve castability, reduce weight, and enhance performance, while maintaining strict adherence to original design intent.

- Material Expertise: Guidance on selecting the most appropriate stainless steel grade or other alloys for specific mechanical properties, corrosion resistance, and thermal requirements.

- Prototyping and Validation: We offer rapid prototyping services to validate designs before full-scale production, reducing lead times and minimizing development costs.

- Secondary Operations Integration: Seamless integration of post-casting operations such as CNC machining, heat treatment, surface finishing (e.g., passivation, electro-polishing), assembly, and specialized coating to deliver ready-to-use components.

Vendor Comparison: Selecting the Right Partner

Choosing the right oem precision casting vendor is a strategic decision that impacts product quality, cost-efficiency, and supply chain reliability. A thorough evaluation of capabilities, experience, and commitment to quality is crucial.

Key Vendor Comparison Parameters

| Feature | Our Offering | Typical Competitor |

|---|---|---|

| Certifications | ISO 9001:2015, PED, NDT Level II certified personnel | Often only ISO 9001 |

| Material Expertise | Extensive range of stainless steel (304, 316, 17-4PH, Duplex), carbon, alloy steels, and nickel-based alloys | Limited to common stainless and carbon steels |

| Dimensional Accuracy | Consistent ±0.005 in/in (first inch) and better via secondary machining | May vary, often wider tolerances |

| Post-Casting Capabilities | Full-service CNC machining, heat treatment, surface finishing, assembly | May outsource or have limited in-house options |

| Lead Time (Average) | 4-8 weeks (tooling & samples), 3-6 weeks (production) | Often longer or less predictable |

| Customer Support | Dedicated project managers, DFM support, 24/7 technical assistance | Standard support channels, less personalized |

Application Case Studies

Our expertise in stainless steel precision casting has led to successful partnerships and innovative solutions across diverse industries.

-

Case Study 1: High-Pressure Valve Components for Offshore Oil & Gas.

A major oil and gas client required complex valve components resistant to extreme corrosive environments and high pressures. We engineered these parts using Duplex stainless steel (2205) via oem precision casting. The result was components with superior mechanical strength and stress corrosion cracking resistance, extending valve service life by 30% and significantly reducing maintenance costs in harsh offshore platforms.

-

Case Study 2: Sanitary Pump Impellers for Food Processing.

For a food and beverage equipment manufacturer, we produced sanitary pump impellers from 316L stainless steel. The challenge was achieving a very smooth, crevice-free surface finish to meet stringent hygiene standards. Our precision casting process, followed by electropolishing, delivered impellers with an Ra < 0.8 µm surface finish, ensuring compliance with FDA regulations and enhancing pump efficiency by reducing cavitation.

-

Case Study 3: Robotic Arm Joints for Automation.

An industrial automation company needed lightweight, high-strength robotic arm joints with intricate internal structures for cable routing. Utilizing 17-4PH stainless steel precision casting, we delivered components with exceptional strength-to-weight ratio and dimensional accuracy, reducing the overall weight of the robotic arm by 15% and improving its speed and payload capacity.

Commitment to : Expertise, Experience, Authoritativeness, and Trustworthiness

Our operations are built on a foundation of Google principles, ensuring that our clients receive not just products, but solutions backed by unparalleled industry understanding and reliability.

Authoritativeness and Expertise

- Certifications: We operate under a robust ISO 9001:2015 certified quality management system, ensuring consistent quality across all processes. Our facility is also PED (Pressure Equipment Directive) certified for pressure-bearing components, further validating our capability for high-stakes applications.

- Years of Service: With over two decades of dedicated service in the precision casting industry, we have accumulated invaluable experience and refined our processes to meet evolving industrial demands.

- Advanced Testing: Our in-house metallurgical lab features state-of-the-art spectrometers, CMM machines, tensile testers, and full NDT capabilities (X-ray, Ultrasonic, Magnetic Particle, Dye Penetrant Inspection) operated by ASNT Level II certified technicians. This ensures every batch of stainless steel casting precision casting meets or exceeds specified mechanical and material properties.

Trustworthiness and Customer Support

-

FAQ Module:

-

Q: What is the typical lead time for a new precision casting project?

A: For new tooling and sample production, lead times typically range from 4-8 weeks. Once samples are approved, production runs are generally 3-6 weeks, depending on complexity and order volume.

-

Q: What file formats do you accept for custom designs?

A: We accept most standard CAD formats including STEP, IGES, SolidWorks, AutoCAD DWG/DXF, and PDF drawings.

-

Q: What warranty do you offer on your precision casting products?

A: We stand by the quality of our products with a standard 12-month warranty against manufacturing defects, provided the components are used under specified operating conditions. Extended warranties can be negotiated for specific projects.

-

Q: What is the typical lead time for a new precision casting project?

- Lead Time & Fulfillment: Our optimized production scheduling and robust supply chain management ensure reliable and timely delivery. We work closely with clients to establish realistic lead times and fulfill orders efficiently, even for high-volume or expedited requirements.

- Warranty & After-Sales Support: Beyond our product warranty, our dedicated customer support team provides comprehensive after-sales assistance, technical advice, and rapid response to any inquiries or issues, ensuring complete customer satisfaction.

Conclusion

OEM precision casting, particularly with stainless steel, offers an unparalleled solution for manufacturing complex, high-performance components. Its ability to deliver superior dimensional accuracy, excellent surface finish, and design flexibility, combined with the inherent benefits of corrosion-resistant materials, positions it as a cornerstone in modern industrial manufacturing. From the rigorous demands of petrochemical and aerospace industries to the stringent hygiene requirements of food processing and medical sectors, precision casting proves its value by enhancing product longevity, reducing waste, and driving innovation. Partnering with an experienced and certified vendor ensures that these technical advantages translate directly into tangible benefits for your business, solidifying your competitive edge in a dynamic global market.

References

- Smith, J. C. (2022). “Advances in Investment Casting Technologies for High-Performance Alloys.” Journal of Manufacturing Processes, 78, 123-135.

- International Organization for Standardization (ISO). (2015). “ISO 9001:2015 Quality Management Systems – Requirements.”

- American Society for Testing and Materials (ASTM). (2021). “ASTM A743/A743M Standard Specification for Castings, Iron-Chromium, Iron-Chromium-Nickel, Corrosion-Resistant, for General Application.”

- Global Market Insights. (2022). “Investment Casting Market Size, Share & Trends Analysis Report.”

- European Pressure Equipment Directive (PED) 2014/68/EU. (2014).

Hebei Mingda International Trading Company is a trading company which is specialized in castings, ODM Ductile Iron Manhole Cover forgings and machinery parts.Our products include all kinds of raw castings to be made of ductile iron , grey iron , brass , stainless steel and aluminums, machined castings and forged parts .ODM Ductile Iron Covers To make these parts according to the customers’Custom Iron Casting drawings , we have relative suitable production craft and equipments, such as resin sand , sand mould , hot core boxes , lost-wax , lost –foam and so on Iron Casting Manufacturer Custom.Specially for hydrant bodies and valves’Ductile Iron Manhole Cover Manufacturer bodies, we have collected rich experience for these products in the past 16 year’s actual production, Now we are proud of our products with good surface and high quality material. Iron Casting ManufacturerWhatever,we have been trying our best to provide our customers with better quality castings by improving production crafts and more careful quality control.Cast Iron Castings Manufacturer|super blog